@elliottbnewcombjr it's a 9" arm..... "maybe" a 10" could fit under the dust cover but a 12" it's not possible if you want to use the dust cover as well.

Turntables: 2 Tonearms. What do you Have or Know About?

……………………………………………………………………………………………………..

Turntables: 2 Tonearms. What do you Have or Know About?

……………………………………………….

I think it would be interesting/fun to create a list of 2 Tonearm TT’s

(2 arms or potential for 2 arms or more)

Links to Virtual Systems; Links to ‘For Sale’; Links to Manufacturers Sites; Photos

......................................................

To Insert Photos, here’s how:

How to Insert Photos in Audiogon Posts

ALL CREDIT TO DOGBERRY

I’m an old man (74), U can do it.

Hopefully this makes sense

INSERT Photo in an Audiogon Post

- Write some yap about your subject

- Open a new Window

- Find a Photo already uploaded to the web

- Yours (my flower)

- Any photo (DBX Speakers)

- RIGHT CLICK on the PHOTO

- Popup menu appears

- ‘copy image address’

- Back to Your Audiogon Post

- Click in Top bar: 6th icon from left: (mountains with moon)

- Popup window appears

- Paste URL in the box

- Size is automatically inserted by the software

- OK

- SAVE

………………………………………………………………………..

My 3 Arm Turntable: Became the Jewel of my System, 8th Photo Here

https://www.audiogon.com/systems/9511

…………………………………………

How did this happen? Covid Times, I upgraded eveything).

I listen to a lot of Jazz, both Stereo and Mono.

After learning here the advantages of a true mono cartridge, I wanted a second tonearm for a MONO cartridge ‘ready to go’. Got big plinth made for 2 arms, JVC VICTOR PL-2. Stereo cartridge on right, Mono cartridge rear.

Then I resurrected a MM Cartridge (new stylus from Jico). Squeezed an 'illegitimate' third tonearm on.

Right long arm is MC (fixed/difficult adjustments);

Rear Arm is MM (removable headshell/easy and quick adjustments of Tracking Force, Anti-Skate and VTA).

Left side arm MONO (fixed/difficult adjustments)

;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;;

dwettecongrats, it's going to be a treat moving instantly from one cartridge to the other.

best-groove it looks like the rear can be a longer arm. and, a dust cover which is a must for me. | ||

I've had a Clearaudio Ovation for years, and just ordered an Innovation Wood (black/piano black). It's coming with a 12" Universal, plus an extra arm-board for the 9" Universal I have on my Ovation now. My Lyra Atlas Lambda SL will go on the 12" arm and a mono cart is on order (due in a couple weeks) for the 9" arm. | ||

pindacFor a very long arm, say 14", it would be a nice option for many turntables. The web site says both arms on the standard design can be 12".

https://dohmannaudio.com/helix-one/ That's unusual for a design without cantilevered arm boards, Those extensions some TTs have/offer make the issue of a dust cover even more problematic. My long arm is 12.5", it requires careful measurements. I can fit that arm on my JVC CL-P2 two arm base; however, it is too long for the 3 arm Plinth CL-P3 my friend is restoring. JVC moved the right side arm board closer to the spinner in order to add the left side arm board (which moves the top right corner closer to the spindle. | ||

It looks like the Helix Design Team could look into producing a Side Bar Cantilever Armboard that attaches into the existing Tonearm Board Mounting. Such a Armboard that has the Cantilever extension will create a design seen commonly in use today and enable longer TA's to be put into service. One produced from Panzerholz or a equivalent material will be a very attractive option. | ||

drbond seems both arms can be 12", many only one arm can be long (like my JVC CL-P2 Plinth. My friend is restoring their very rare 3 arm plinth CL-P3, only one can be long on it. nice to know, simply unusual looking, I went to their site and read a bit. I don’t see a dust cover, is one included or optional? | ||

paulietunesgorgeous wood, congrats on your enthusiasm to have something different and excellent. | ||

@tomic601 The individual that I refer to as the Godfather of using P'holz for Audio use, has supplied information on their Qualia Labs Website about many materials measured damping/dissipation. Their follow up exchanges that can be found on various forums, strongly siggests that when it comes to Board Thickness, a 10mm Board Thickness, is all that is required for a Phenolic Resin Impregnated Densified Wood (PRIDW) to attain the most desirable measurements for Audio Purposes. I have been demo'd plinths made from Laminations creating a 35mm Board Thickness and from a typical production Board Thickness in both 25mm and 32mm. The detected differences on a Sonic in these thicknesses, are not as immediately discernable as when a PRIDW Plinth is compared to a standard Birch Marine Plywood, or a non-resin impregnated increased in compression Plywood. I have a PRIDW Board of a 75mm Thickness, this is selected to embed my TT's Motor Unit into when I put together my own SP10 MkII Kaneta Design.

| ||

@pindac sorry for slow response. I have so far somewhat limited experience combining various thickness of Panzerholtz with HRS ( Harmonic Resolution Systems ) products - Typically NIMBUS couplers. So far i have had sonic rewards by reloading my NAS, Optical Isolation, ROON Core and a variety of Linear PSU on to 20 + MM Panzerholtz shelves / platforms. Hopefully this helps. my analog components all utilize CORE audio and or HRS products. Best to you - I always enjoy your excellent contribution here Jim | ||

@pindac sorry for slow response. I have so far somewhat limited experience combining various thickness of Panzerholtz with HRS ( Harmonic Resolution Systems ) products - Typically NIMBUS couplers. So far i have had sonic rewards by reloading my NAS, Optical Isolation, ROON Core and a variety of Linear PSU on to 20 + MM Panzerholtz shelves / platforms. Hopefully this helps. my analog components all utilize CORE audio and or HRS products. Best to you - I always enjoy your excellent contribution here Jim | ||

I have been trying to find a settlement with the idea of a Cantilever Sidebar TA Mounting Arm Board. The Bolt Down method commonly seen is simplistic and hopefully is not compromised as a design. I have a design in place for one of my Panzerholz Plinths to receive a Cantilever Side Bar TA Mount, where I have attempted to avoid the usually seen Bolt Down Fastening of the attachment. My design which lends itself quite nicely to being done in P'holz, is a interference fit Mortice and Tenon with a Flange to receive retaining fastenings into threaded inserts placed into the main plinth, as well as having two threaded inserts, inset into the Side Bar flange to receive fastenings to help release the part when not wanting it attached. The idea is for there to be a few parts produced, to be exchangeable, enabling working with differing lengths of Tonearm. Slots to be used for allowing setting up varying length TA's in Plinths or Arm Boards are something I have commenced avoiding quite a few years past, all leads back to the rigid coupling principles. My last two produced Plinths have extremely tight tolerances machined into the Plinth to receive the TA that is now used. The Producer of my most recent produced Plinth, has an identical dimension Plinth > TT > TA and they are settled with a Slot in their Plinth. Each to their own when it comes to such subjects. I will be in a position to learn if a sonic is affected between a Plinth Mounting and Side Bar Mounting a TA, I will be settling with that as the only goal.

| ||

sksos that’s the 1st 4 arm TT I/we have seen here from their web site

many variations shown there https://www.kuzma.si/stabi-r-world-premiere-munchen-2018.html ’non flexible belt’. ............................................. I have a vintage 1958 Viking 75 (telex) 2 track stereo Tape Deck (play only) that came out of my Uncle’s Fisher President II that I inherited. It has a ’non flexible flat belt’, the outer one of this set. https://www.amazon.com/Replacement-Belt-Viking-Reel-Player/dp/B07GVJLCH4 ............................................. Tape Deck was from the ’crossover’ era: ’In-Line’ or ’Staggered’.

This shows 1. an erase head left (both tracks); and 2. centered: an ’in-line head’ (both L and R tracks ’in-line’ vertically (the final 2 track/half track accepted version) 3. 3rd head, one track only,, to the right, further along (staggared) ........................................... 4. Deck had a switch: a. ’in-line’ position used the center 2 track head for stereo playback, 3rd head disabled. b. ’staggered’ position used one track from the centered head, and the other track from the single track head further along. 5. eventually ’staggered’ method lost and the 3rd staggered head was eliminated. ........................................ I have a small collection of 2 track stereo tapes, some marked ’in-line’ and some marked ’staggered’ that came with the Fisher Console. They are not 15 or 30, but Pre-Recorded 7-1/2 IPS. They sound fabulous.

| ||

@tomic601 Can you offer a assessment of your experience with Panzerholz. I am a advocate of this material and encourage the use of it for audio purposes. | ||

Elliott - The plinth was made in Italy including the very well machined aluminum arm boards. the veneer is apple from Germany. Peter does some amazing plinths. He is a fellow member of San Diego Audio Guild… a true renaissance man ! i am working on some Panzerholtz armboards…. best to you….. a fun and great thread…. | ||

tomic601 that's quite a system you have put together. two of fthe Dynavector 505 Tonearms, I just looked at OEM's setup instructions, whew! https://www.dynavector.com/etechnical/505manual.html You mentioned Peter at PNB. Did he make the custom 2 arm base?

| ||

My setup for 78 RPM audio restoration: Technics SP-10R in Albert Porter panzerholz plinth Primary arm: Fidelity Research FR-66S direct-wired with Shure V15 Vx and dozens of custom Expert Stylus stylii with various truncated elliptical and conical geometries Dynavector DV505 with Soundsmith Strain Gauge cartridge and about a dozen custom stylii wth similar geometries. Just got the Strain Gauge and have been testing it...with a few easy tweaks, it can easily work for acoustical and early electrical recordings. You just have to invert the RIAA treble and add in the period curve. I use CEDAR Cambridge and can do it live but prefer to do it all in post via Scott Wurcer's hyper-accurate curves published in Linear Audio magazine. S/N ratio seems to be an improvement on the Shure, but still evaluating. Early signs are great--very similar frequency response to the Shure, and great transient response. Vinyl 78s are almost tape-like...groove tracing seems to be on another level. I'm going to temper my enthusiasm until a few audio engineer friends weigh in!

| ||

I’ve shared info about P’holz and Equivalent Materials, in other threads. There are Brands creating the Densified Wood Products using very closely followed production methods as used for P’holz. I recently offered a Gon Member a Free Sample of Permali, preferably to be used as Sub Plinth, at a dimension of their choice. This was a sample I was offered by a individual who is producing Densified Wood parts to work within an Audio Set Up. It would have been good to have received a feedback from somebody who has a experience of Vinyl that I admire, but the offer was not responded to. The Goldring Lenco GL 75 is seemingly well supported with Permali Parts by this individual. I have been very impressed with a P'holz Puck Weight when compared to a Zavfino Puck. The Permali is available, produced as a Peripheral Ring, which could be very interesting. | ||

Luxman PD-555 (1st one I've seen)

https://www.usaudiomart.com/details/650001505-stunning-legendary-luxman-pd-555-vacuum-turntable/

| ||

A clearaudio with 2nd arm board waiting, asking $3,800. (3 extra armboards, no tonearm(s) included)

a DUST COVER, yay!

https://www.usaudiomart.com/details/650001510-classic-clearaudio-reference-turntable/

| ||

| Post removed | ||

Fortunately for myself I have not gone to great expense for my equipment support. Much of the materials in use are selected from trialing and elimination of materials. When a Material is discovered that has a impact on the sonic that is desirable to myself, I will then attempt over time to discover the same material type in different dimensions and assess the impact it has. Granite used as Tier in a Support Structure, certainly does offer something quite special for my needs when used in a Mass, not usually considered to be used. Even a Tier used on my support plinths for a Cabinet Speaker has shown to be much more beneficial when it is a substantially increased thickness used over the earlier samples of 20mm-40mm. Extra Thick Granite used in such a position is still a little user friendly, it is the Speakers Weight that 'hurts good'. | ||

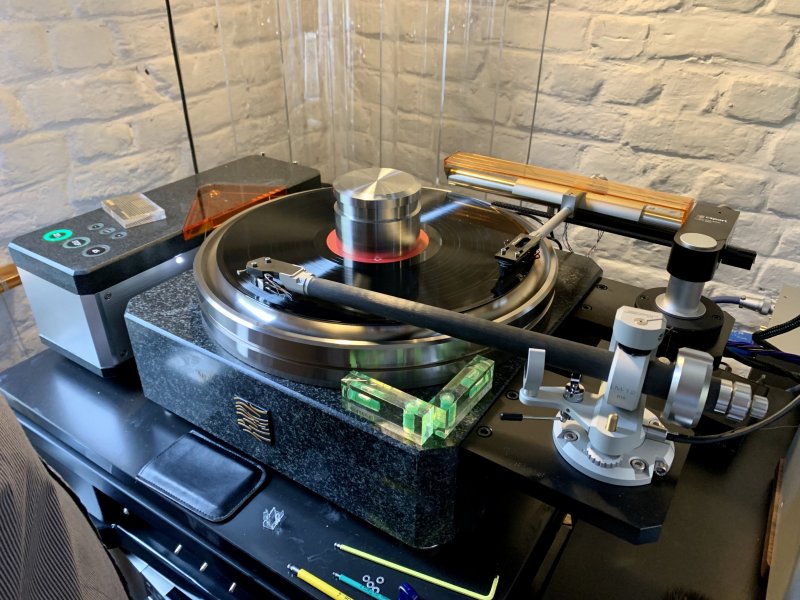

pindac OVERKILL: (websters): ’Found under the equipment rack’ My final TT support, to deal with my springy floors, drop the needle, "gimme 2 steps..."

Notice, my TT’s oversized plinth is on a deeper glass top I had made, it cantilevers a few inches over the back of the normal depth ’glass topped’ racks below. Fortunately the Spinner’s weight is forward, so luckily no rear support under the back edge of the glass was needed. I designed and built the racks below it, 3 heights

They can surround equipment with some heat, they are ventilated, wide open in the back, see my tube preamp below my tube amp.

lower equipment pulls forward without disturbing upper unit

other photos here https://www.audiogon.com/systems/9703 anyway, hard not to digress, but to note, many TT’s that take multiple arms need more space, depth, or width, like my friend’s Luxman PD444

My OEM dust cover is lift off, Luxman's is hinged

| ||

@elliottbnewcombjr I would like to say, I learnt my lesson with Granite Monoliths. That is a tale I can't tell, I have a 250Kg Granite Lintel/Engineers Plate, used as part of the support structure for the 845 Monoblocks. The equipment Racks are seated on Steel Plates of a dimension 900 x 700 x 15 (36" x 28" x 5/8") again a Holiday is needed following the experience of being put in place. I am hoping my 'new kid on the block' - 'go to' material, is a worthy substitute for these when I return to using the system. | ||

As for the 401 given a Ferrari Badge, hopefully only to suggest the Colour is a match to the Brand. "Beauty is in the eye of the Beholder". I had the same model Polished Silver mounted on to a 9 Stone Granite Plinth. During the 90's Slate was the fashionable stone at this time for an Idler Drive , but I have always had a good experience with Granite used in a structure. It was quite expensive to maintain, as a visit to a Chiropractor was required each time it was manoeuvred of the Racks Shelve. Even worse, the home at this time, was with a Listening Room on the Second Level. | ||

lewmGarrard, not Lenco, but I get that you don't think it should even exist. | ||

dogberry thanks for the history. so simple looking, yes pocket emptying! I would have made one of the tonearms removable headshell. My rear arm, removable headshell is the Acos Lustre GST-801, uniquely using magnet force for both tracking force and anti-skate. It's raise/lower mechanism is wonderfully simple. Help here knowing about and finding one to buy! https://reverb.com/item/32656865-acos-lustre-gst-801-tonearm-rare

| ||

Thanks for the credit in the OP @elliottbnewcombjr, but I should note that whilst you might be the one that is 74, I am not, being a mere youngster of 65! Two tonearms? I had an expensive journey in that regard. I started it with an SME 10 turntable and an SME V arm, and I was very happy with both. I’ve written before that it sported a London Decca Reference cartridge and I was completely happy—until the Reference needed to go for a rebuild, and John Wright announced his retirement. So I went on a cartridge journey and ended up with several candidates for when the Reference might finally die and be unrepairable. While there is now a new owner and the Reference might be serviceable in the future, that was not the case at the time so I decided I needed to use the other cartridges to spin out its time with me. There was once upon a time the option of adding a second arm to the SME 10:

There’s a sad story to that, though. The maker was an SME dealer, and when SME saw what they were doing they took the dealership away from them, so they stopped making this useful accessory. So I bit the bullet and bought a second SME 10! Used, of course, and with the M10 tonearm, which is much like a 309. Even so, when the Reference came back, I still wanted to house the Nagaoka MP-500 that sound so good, and I also had a Grado Statement 3 and a SoundSmith Sussurro MkII, plus an Ortofon Cadenza Bronze.....what to do? I ended up ordering two tonearm pods from this place: https://www.acoustand.co.uk/products/tonearm-pods-for-all-applications-premium-product and mounting two Rega RB330 arms on them, as I cannot buy any SME arm except for the M2 (which now costs more than the SME V did!) So I can run the Reference, and the MP-500 on one table, and the Cadenza Bronze and a Cadenza Mono on the other.

The second photo does not show one other necessity: the Cadenza Mono will not balance with the stock counterweight of the RB330 (there’s a .50cal lead ball taped on the back of the arm in the photo, but that arm now sports a 150g Groovetracer counterweight. I’m happy. Some say that tonearm pods are a horrendous nightmare, but these sit on points on top of a 400lb oak chest, and the differences between the cartridges are clear, and I can not say the MP-500 or the Cadenza Mono are in any way hampered from showing their metal by their homes. | ||

Wave Kinetics, 2 arms

https://www.whatsbestforum.com/classifieds/wave-kinetics-nvs-reference-turntable.719/ forgot to say, at some point I switched back to USA | ||