I just had a knee replaced and shoulder muscles reconnected. I am way far from being upset with anything.

The "Very Best Record Cleaning Formulation"

The "Very Best Record Cleaning Formulation"

I am providing this formulation for all who are interested in the very best, and can be proven and demonstrated to be the "Very Best". It can easily be made from available ingredients. On the surface, it appears to be very simple. However, it is based on extensive complex chemistry along with precise mathematical calculations and verifiable data.

You may use it with absolute confidence and be truly assured that it is beyond doubt the "Very Best". You may use it for your personal needs. Or, archival entities may use it for their purposes with confidence. Or, you may choose to start an enterprise that makes and packages quantities as either a "ready-to-use" or a "Semi-concentrated" version for sale and distribution knowing that nothing better exists. You have my blessings and encouragement with one condition. And, that is, that the pricing represents a "fair margin", and, not an obscene gouging, typical for such products.

Initially, I had prepared a presentation that briefly introduced myself, and provided the thought processes, design parameters, and the necessary basics of chemistry, physics, and mathematics to assure you and allow you to be absolutely confident in this formulation. I made a considerable effort to keep it as simple, but, also as thorough enough to achieve this confidence. However, that presentation entailed 5,239 words, typical of such a requirement, however, unacceptable in length by this website forum.

I have no option other than to offer the formulation as a 100% parts by weight version suitable to produce 1 Kilogram of the cleaner, and, invite you to question me about any aspect of the formulation.

Professionally, I am a Chemist, more specifically a Polyurethane Chemist. I have a Doctorate in Chemistry as well as two other Doctorates and a M.B.A.. I held prominent positions in significant corporations before being encouraged to start our (wife and I) manufacturing facility servicing those I previously worked for. We started, owned, and fully operated this business. We eventually obtained 85+% Market Share in our sector in Medical, Automotive, Sporting Goods, and Footwear areas before retirement.

The Audio Industry is extremely technical and many brilliant minds have contributed their talents over the decades in order that we may enjoy music today as we choose. Like many other technical industries, those of lesser minds and values invade the arena with their "magical" inspired revelations and offer their "magical" ingredients and items to all at extremely high prices. They promise that if only we are willing to part with our money - they can provide these items to you that make your audio system sound as if the orchestra, or vocalist, is in your room with you. And, after all, "magical items" must be expensive, otherwise, they would not be "magical".

This disturbs me enormously, and, it is for such reasons, I feel compelled to provide realistic and truthful information that conforms to basic Engineering, Chemistry, Physics, and Mathematical Principals in those areas with which I am very knowledgeable and familiar.

"Ultimate Record Cleaner Solution"

Ingredient Amount by Weight (Grams)

Distilled Water 779.962

Ethyl Alcohol 220.000

Tergitol 15-S-7 (Dow Chemical) 0.038 (Approx. = 2 Drops)

1,000.000

Important and/or Relevant Criteria

1.) Distilled Water ONLY. Do not use deionized, tap, rain, or spring water. Distilled Water is readily available in most grocery stores. Check labeling to be certain that it is distilled and not deionized. The pricing is comparable.

2.) Ethanol must be purchased at a "Liquor Store" or a "Liquor Control Board" that is suitable for human consumption, and the appropriate taxes must be paid. This assures that the alcohol consists of only Ethyl Alcohol and water. You need to purchase the 95+% version, also known as 180+ Proof. NOTHING ELSE is acceptable. (100% Ethyl Alcohol is not available under "normal" circumstances). Denatured alcohol from a Hardware Store or elsewhere is PROHIBITED, as well as ANY other alcohols.

3.) Tergitol 15-S-7 is made by Dow and is available on the internet in small quantities from Laboratory Supply Houses such as Fisher and Advance, etc.. I have no affiliations with either Dow Chemical, or Fisher, or Advance. You MUST use Tergitol 15-S-7 ONLY. No other Tergitol product is acceptable for this designed formula, and you need to acquire the undiluted form only.

4.) The above cleaner formula will result in a non-foaming (VLF) Surfactant Formulation that exhibits the following:

Surface Tension of 28.5 dynes/centimeter @ 20 C. (68.0 F.)

Surface Tension of 28.2 dynes/centimeter @ 25 C. (77.0 F.)

5.). A Surface Tension of 28.5 dynes/centimeter is Remarkable and will properly clean records of all organic soilings, and all oily substances, as well as very significant amounts of inorganic soilings. This available Surface Tension coupled with the Azeotropic Characteristics of very rapid evaporation and spotless drying occur because of the selection of Ethyl Alcohol and the very specific concentration determined as 22.00% p.b.w., further improves the products abilities. The "Ease-of-Use" and "Spot-Free" results are to be accepted.

6.). Be aware that an "ideal temperature of use" also exists for this formulation. And, that reasonable temperature is 40 C. (104.0 F.). Further increases in temperature offers no improvement, therefore, confirming the proper use of the term "ideal". I mention this not because of of any substantial improvement, but, only to be aware of its’ existence. And, if you have a choice to utilize a room that is warmer than another, select the warmer room closer to 104.0 F. There is no need to elevate the temperature of the records or the materials. Simply be aware that 104.0 F. Is ideal.

If interest is expressed in this submission, I am willing to provide additional submissions regarding other materials, and, other areas of interest. Such as"Best Contact Substance", "Best lubricants for turntables", " Better Dampening Materials" for turntables and tonearms, and, most significantly, "Best" material for "Turntable Platter/Vinyl Record Interface" usually called "Record Mats". The last item will certainly disturb many individuals and anger many suppliers.

Whatever I may contribute is substantiated by Science and Testing, and Verifiable. Science has no Opinions. Opinions in these matters are best reserved for those who rely on their imagination and wishful thinking.

Also, I have no vested interests in this Industry. Simply possess some scientific knowledge that also relates to some aspects of the Audio Area, and I am willing to share that information if requested!

You're attempt at using the infamous "Benson Quayle" debate line as an insult is pathetic. Just make sure you tell U.S. Navy and NAVSEA that they were wrong to award me the Engineer of the Year twice which no one else has ever done, or to use the manuals I wrote for the design of some nuclear submarine fluid systems, or to use the host other documents and designs that will be in-use and in-service with some to the end of this century. Otherwise, now that you are back, having not abandoned people, and you claim this forum-post as your own, I have no reason to further participate which should just make your day. |

As with @lewm I also prepared a response that I will need to submit later today. More like this evening. I realize that your post was the last before "the void" and I wanted to respond much, much earlier, but I also needed to vent my frustrations and attempt to place this Forum in the context for which it was intended. Perhaps it was futile, but, I needed to try one more time. Since this Forum attracted more views in less than two weeks than "Mr.W's" forum did in over two years, it was understandable that he would "coattail" a popular site to post his postings. But, the interference in the intent of THIS forum was getting out of hand. So, I hope you are not terribly upset that I did not respond to you sooner, and I request your forgiveness and we can get back to reality. You will. have your explanation soon and proposed recommendations. Thank you for listening, and, I hope you are not terribly upset. Wizzzard |

Did it ever occur to you that the size of a drop would be different from different eye-droppers, let alone a precision pipette? I know that because I have measured it and others have also. Of course, not with the extreme accuracy of scientific scale, but with a simple digital VTF scale. Drops can easily be in the range of 0.03 to 0.06 mg/drop by measuring 10-drops and then dividing by 10 (to ensure the reading is in the range where the device has some reasonable accuracy). The simple benefit of the Nalgene Dropper Bottle is that it delivers a fairly accurate 0.04-ml/drop - Factors to consider in accuracy and precision of Nalgene Dropper Bottles (thermofisher.com). So, the variable of the drop is mostly eliminated - close enough. Otherwise, if you knew "two drops will equal 0.0577 g. which is 52% more than required", given how specific, how scientific you were in the formulation, why did you not provide a tolerance for the composition which is normal engineering practice? Yell, scream, holler all you want, but my responses to people on this thread is to present information in a way that most anyone can hopefully understand. When I trained many people in critical oxygen cleaning processes where death, injury and destruction were consequences of failure, and the deck-plate technician may have only a high school education, you keep it simple. I reference scientific papers for those that may wish to dive deeper. Yes, you and I are wildly different - you are a scientist, I am an engineer. You know what they say about engineers: The optimist will say the glass is half-full, the pessimist will say the glass is half empty, the engineer just says you used the wrong size glass.

|

Thank you for your comments. But,I could not help but wonder what your particular field and speciality happens to be. Do you mind sharing that information. It has been 4 hours since I first read your post, and, you still have me guessing. Obviously, you do not need to respond, but you were the first to comment, and your style of writing and composure is unique. And, as a scientist, we are almost as detectives in nature. So, it you do not mind, your answer would be satisfying, and, in some strange way, I would be grateful. Thank you again. Wizzzard |

@wizzzard I agree as well, that the interest in audio equipment is offering the best experience when kept with the focus on the replay of the recordings and the resulting emotions that can be evoked by the period of listening, of which one emotion stimulated can be enjoyment, but not limited to this only. I do believe the term enjoying the music, has a broader meaning, which is more akin to suggesting one is their better self, if seen to be enjoying the Activity, Hobby, Avocation and not being in contention with the subject, especially not being able to show acceptance of the views and made known practices of fellow like minded enthusiasts. Contrary content will always be discovered, there are many variables and individuals are quite different in their experiences of being exposed to those variables, which will be instrumental in how the individual becomes moulded into their ideas about what has and does not have value. In Psychology would this not be a environmental impact, that has a effect on the development of a person. The interest in audio equipment is quite able for certain types, to open up parallel avenues of interest, especially in how the time spent listening to recordings can be experienced. Seeking out methods to optimise the performance of the critical ancillaries to be used, is a extremely common practice by individuals interested in audio, for some it is very important stimulant and fits into their interest in replays of recorded music like a hand entering a well fitting glove. Your thread is supplying a Topic on a Mixture to produce a Solution that is with claims to be an optimised solution for decontaminating a Vinyl LP. Your academic education and chosen career and seemingly the Cornerstone of this thread. Do keep in mind, in relation to this thread, that you are dealing with the 'short-term past' and the 'now'. In the future there will be individuals from across the Globe, with a developing interest in caring for their Vinyl Collection, discover this thread and like a 'duck to water', commence taking on board your ideas to create a mixture to be used as a cleaning solution. |

@bdp24 @cleeds @dogberry @lewm. @drbond @drkingfish @ericsch @eryoung2k @fleschler @gemoody @jasonbourne71 @jm-audiophilemusiclover @joenies @jwillox @kennyc @kylehildebrant @lewm @llg98ljk @lloydc @mijostyn @mojo771 @moonwatcher @mrthunder @normantaylor @noromance @oilmanmojo @ossicle2brain @pindac @recklesskelly @rhg3 @rich121 @richmon @rtrlover @thecarpathian I apologize to everyone especially @lewm for allowing my emotions and my medical condition preventing the conclusion of my message to Lewm and others on 30 July 2023 @ 4:40 PM I determined that I needed to submit another comprehensive statement explaining my issues concerning the undesirable direction of this particular Forum and that it is not proceeding as intended. I wanted to obviously be totally objective and not allow personal experiences and issues interfere with what should be a purely clinical statement. The following day I logged onto the Forum to be struck by profound but very dissimilar postings. One post was a sincere expression by @lewm that I truly appreciated. The other was a post by a new individual, @drbond, that was very perceptive in its’ nature, and his understanding of both the the objective of the Forum, as well as my visible frustration. His suggestion of listening to music is one of my basic precepts, and his advice in musical selection could not have been better. His selection demonstrated his understanding even further. To the contrary of these meaningful posts was a post made by "Mr. W" which was clearly most disingenuous, even to the extent that it contained an additional caveat to enhance his pretense. Needless to say, I again found myself unable to present any coherent statement that day and waited for another time while debating my intended presentation. The next day I logged in again only to discover matters did not improve as "Mr. W" was now again providing his pontifications to matters that were intended for the Forum initiator. "Mr. W" was now not just continuing to contaminate this Forum with his pontifications from his "collage" he calls a book, to essentially abducting this forum for his own intended purposes because of the lack of interest in his own forum that he started over two years ago. The following days continued in a similar manner, it was at this point that I had an additional thought to consider. Since I was still debating as how to best express myself, I considered to allow the Forum to continue as it had, to see if the outcome would approach my recent thoughts to any degree. Never did I imagine that it would continue for such a period of time without a posting by anyone. I obviously must now interrupt this cycle and post some statement. The last post made was on 6 August 2023 at 9:04 AM. It has now been 22 days without a post even though the views continued at a reasonable rate. One can draw many conclusions from this however I have selected mine. I wanted to understand the fundamental problems that I was unexpectedly having. I now believe I understand, but I must now apologize for the method I selected. I hope everyone understands. I wish to share my knowledge with those that are interested, however, I do not wish to squander my limited time correcting certain individuals even though their incorrect statements can not remain without being corrected. I also need to be careful because my riposte to certain individuals were considered offensive by them that they resorted to tactics to remove previous well expressed explanations of mine to be temporarily removed - I do not wish that to happen again. If you find the time, much of this has already been covered from the onset. It is mentioned repeatedly at the beginning of every page, which is the very first post. You only need to read the last three short paragraphs of the first post. Also, the brief statement I made 16 June 2023, and the rather lengthy, but significant, statement that followed on 17 June 2023 at 4:36 PM. I am fully aware that two separate issues are fundamentally in play, however, they are interconnected to some extent. In common terms there are expressions that are quite appropriate and meaningful, such as, "It only takes one rotten apple to spoil the entire bunch". But, since this is intended to be a scientific and technical Forum, in Chemistry and in Physics there exists the concept of a "nucleating agent". We witness this scientific event every time we prepare pasta. When we bring water to a boil we add salt prior to adding the pasta. The addition of salt at this period causes an "explosion" of millions of tiny bubbles while the salt still maintains its’ crystalline structure and subsides when the salt dissolves. If the salt were to be replaced with crushed glass of the same consistency (not that I would ever suggest doing such) this event would continue unabated. Which brings me to my first segment of my comprehensive statement, that to allow this Forum to continue as intended, we need to avoid the "salting" of the Forum. This individual, "Mr. W", who has repeatedly stated that he would not waste any of his time with any involvement in this Forum, and said his "final farewells" more than once - FINALLY does keep his word and avoids inserting himself and his incorrect comments once and forever! This individuals’ verisimilitudic meanderings contribute confusion by negating basic fundamental scientific realities, and in its’ stead inserting his sanctimonious perfunctory beatitudes is disturbing. These ostentatious presentations of his disguised as sagacious posts are nothing more than pernicious deviations that intend to appear didactic on the surface, are in reality, a supercilious exposure that is extremely destructive in nature of very basic facts, which is a fundamental aspect that is sought on this Forum. This methodology of his, that has obviously served him well in his prior endeavors of his career, is in opposition of my methodology that not only is inherently based solely on substantiated facts but with assiduity and diligence. This methodology of "Mr. W" to attempt to elucidate an issue by continuously providing surfeit data creating a cancatervate of verbiage that is salient of incorrect data and contradicts the basic tenants of TRUE SCIENCE is dangerous and misleading. I encourage those that are besotted by this individual and his postings to be more astute and aware of these incorrect statements presented as facts are nothing more than his misunderstood interpretations of what "others had written". I ask you to carefully parse his collection of "data" and be aware to segregate his biased misunderstood statements presented as factual while truly being incorrect in a multitude of respects. I assure you that I am fastidious and that my statements are factual and verifiable. I may mention the work of others, but, never claim those works as mine. And the verifications are not only based on scientific realities, but also verified by me personally. I would never state something as factual unless I could also verify the statements by my own actions if and when necessary. I would now like to revisit what started this dissertation. After reading Lewm’s sincere message, the disingenuous post from "Mr. W" followed mentioning the "discourse" on Wikipedia about Mr. Hansen. I am relating to actual personal exposures and dealings with these individuals. Working with some of the most brilliant people in the Sciences, as well as with frauds. Personal contacts and personal impressions and interactions, and, "Mr. W" meanwhile is referring me to a comment he read in Wikipedia. And, in this same post he initiates another futile attempt to correct me. (This is not the first time he has made such an attempt but his third). he relates to a "childish reminder" that "20 drops of water is equal to 1 mL of water which is equal to 1 g. of water". He mentions his favorite Nalgene dropper bottle once again. And signs off with a fallacious "Peace". I have had people correcting me on a variety of things. One individual was correcting me about the Degrees issued at U.K. Universities, such as Oxford, never ever even considering that "Wizzzard" attended one of those Colleges at Oxford University where such degrees are/were issued. Another individual attempted to correct me by stating that "Chirurgie" is French not Latin, never stopping to consider that Wizzzard studied Latin for six years and ancient Greek for four years and attended a College at Oxford where some subjects were taught in Latin and Greek. Also, never stopping to consider that Wizzzard is fluent in several languages and "functional" in several others. (Latin, and ancient Greek not included, because they are not conversational). And now "Mr. W" relates "grade school guidelines" about drops and weights, never stopping to consider that I, Wizzzard, actually weighed out two drops of Tergitol 15-S-7 on his $5,600 Sartorius analytical balance. Not just once but five times and taking the average of the five readings. This never crossed his mind because his mind does not even allow such things to ever enter or even be considered. Fact is, that 1 drop of Tergitol 15-S-7 weighs 0.02888 g. So in my presented "Very Best Record Cleaning Formulation" which is based on parts by weight, I state to use 0.038 g. to produce 1 kg or (Approximately 1 Liter) actually 998.203 ml. of cleaning fluid at 20°C, and, I placed in parentheses "Approximately 2 drops". Two drops will equal 0.0577 g. which is 52% more than required. I know, I knew, that at the onset. My formulation is in parts by weight and many individuals, if not most, do not have the equipment to measure such small quantities, therefor, I had to approximate the amount in drops as well. You can not measure half or quarter drops, so it was only logical to state an amount that would be sufficient, and, 1 drop would NOT meet the requirement, therefor, I stated 2 drops. It is not because I do not know how to calculate, or, how many drops should have been stated as "Mr. W" implied on a few occasions. It troubles me that I need to explain such things and wasting my time instead of providing other meaningful knowledge that I would like to share with everyone. I realize that this is a weakness of mine, but, I can not allow such remarks to exist without correction and explanation. This childish nonsense needs to STOP, and it needs to STOP immediately after this presentation. When I indicated that the formulation I presented was done by "design", that was entirely correct. I needed to take many things into consideration including the hundreds of formulations incorporated into "Vinyl LP records" over the years and also the hundreds of additives that were used to establish what was to be considered as a "most encompassing vinyl compounded formulation". One of the main objectives was to "do no harm to the recording" besides developing the very best cleaning formulation for such a substrate. This was all very carefully considered before beginning to formulate the cleaning formulation. I did all the necessary mathematical calculations to determine what can be used and to obtain the lowest Surface Tensions at 20 C. and 25 C. BUT, I also had to verify the calculated design by actually measuring the Surface Tensions at the intended temperatures. I did so by using my Stalagmometer developed in the mid 1800’s to measure Surface Tension of liquids and is still the primary device used to this day. I also had to follow the very detailed proper procedure required to obtain the precise Surface Tensions. The Surface Tensions that are stated in conjunction with the formulation presented, are those that were actually measured, by me, using my Stalagmometer. Yes, the mathematical expectations and calculations were very close to the measured values, but, only the actual measured values were stated. I stated only the actual measured Surface Tensions. That is what I refer to as Verification. I hope you can understand why I get upset when someone, or, when someone’s devoted followers questions my statements as mere "suppositions" that require questioning or correction. Also, as any good Chemist, I use a Stalagmometer to determine the amount of drops required as well to see how it also correlates. A Stalagmometer is a pipet device that has a bulbous midsection with a capillary bottom and a standard upper portion. It comes in three sizes and I have all three with duplicates of #1 and #3. An A.S.T.M. method requires specification of type used for very technical presentations, and, since #1 is used about 95% of the time, and, this was not being presented to The American Chemical Society, but to audiophiles, I found no need to state unnecessary info and clutter a "simple post". I am bringing these matters up only now in order that you understand and appreciate my efforts to be thorough in order that you can have absolute confidence in my statements. I found no need to bore you until this provocateur "Mr. W" has forced me to write these unnecessarily long explanations in order that you may discount his interruptions and have the confidence I seek in those that read and post in this Forum, and are requesting additional information. Also. "W" keeps referring to the explosive nature of a 22% solution of Ethanol in water, and continues to bring up "Flash Points". Never once being specific as to whether the "flash point" was determined as a "Closed-Cup" or "Open-Cup" flash points. Now back in the days when I attempted to communicate with him, he was extremely offended when I asked him about his Academic qualifications. Since I am keeping my promise unlike his (which has no meaning), I wonder how offended "W’ would be if someone asked him how many "flash point determinations" he has made personally, and, not something again that he had read on Wikipedia? The day after I turned 14 years of age and received my Social Security Number, I started working at a Public Library (part time) for $27.50 per week on average. Later that same Summer at the age of 14 I began work at a major chemical company. All starters at this company, with the exception of those with their Phd’s or those that were recruited, were required to work for 5 weeks in the Quality Control Lab before moving to an assigned Lab. Whether you had your Masters or your Bachelor’s or nothing - this was the requirement by the C.E.O. of the company to familiarize yourself with all incoming raw materials including solvents, and intermediates produced, and finished products, including water-bornes that contained solvents, etc.. It was a great introduction. The Lab had individuals that worked only in Quality Control as well as the 5 week transients that moved on to other areas. One of the many tests I learned to preform was "flash point determinations", both Open-Cup and Closed-Cup. Other tests included measuring Surface Tensions of Liquids including solvents, and solvent blends, and intermediates via the method I previously mentioned as well as other methods. "Bottom Line ", at the age of 14, I preformed hundreds of both "Open-Cup and Closed-Cup Flash Point Determinations" that Summer before being transferred to "The Conductive Lab". I was paid $136.00 per week. That was a lot of money for a 14 year old in 1958 as a Summer employment job. So, you might say that I have a pretty good understanding of "Flash Points" even at a very early age, and also had an excellent understanding of the results and their significance. So, who is going to ask "W" how many "Flash Point Determinations" he has done personally, but, more importantly, what is his understanding of results, if any. I have a notion that this question need not be asked, and I believe I already know the answer based upon his previous comments. Another point that "Mr. W" had made that ruptured a blood vessel in my brain on 8 July 2023 at 3:35 PM, and I paraphrase, "Vinyl record is a co-polymer of PVC and PVA". As I have stated many times do not make statements that you know absolutely nothing about. Since "Mr. W’s" "book" is primarily a collection of works of others with inserted charts and graphs, and references to papers and other documents with notations of additional material that must or should be looked into, I do not know who is actually responsible for this monumentous error. Is "W" the initiator, or, is he just parroting statements of others, because I have noted this error at other locations and papers, therefor, I am in no position to pass any judgement. However, it is an excellent example of a terrific error not being corrected immediately and subsequently allowed to flourish unchecked. I will now correct this once and forever. "Vinyl LP records" are NOT MADE of a Co-Polymer of PVC and PVA. PVC (Polyvinyl chloride) is a Homopolymer. PVA, or more correctly PVAc (Polyvinyl acetate) is a Copolymer. The mixture of both is NOT a Copolymer. In Industry, a blend of these two ingredients is most frequently referred to as an "Admixture"! Stating that it is a Copolymer is an enormous and important mistake, because, if that were the case it would be impossible to process as vinyl pressings are made. [It is my understanding that LG has been able to make a copolymer very recently with limited success in 2019 to reduce costs of enhanced PVC products by avoiding incorporating specialized polyurethanes that make the end product more expensive.] An addition of 8% (plus or minus) 1.5% significantly upgrades the physical properties of PVC polymers. (I might add that I am the original developer of these specialized polyurethanes to be incorporated into PVC components). If LG can develop a more extensive range it would allow upgraded PVC’s to be made for a little less money, but, the volumes of PVC are substantial, and, basically this little amount of money can actually become in total a lot of money. I apologize for deviating, but you see this development is very new and limited in scope, but, still would never be able to be processed as records are made. Now onto another statement by "W" when discussing with @mijostyn about a "typical" vinyl formulation developed by RCA in 1976 (one point) and using epoxidized soybean oil which is "very stable" (second point). This formulation is probably one of the worst examples of something that is "typical". From what I have gathered, there appear to be many serious audiophiles who are well educated far beyond the norm and many appear to be of an older generation based upon their statements. I am certain that many may recall "RCA Dynaflex" and the "wonderful sound" of these thin flexible recordings. Yes, I am being factious! Well that is the formulation presented as typical. How many of you have any in your collection? Using epoxidized soybean oil - how cheap can you get. I assure you, off-hand I can not think of anything less expensive, other than the Toluene, that was also used as a "plasticizer". Now this is a very remarkable technical subject, and, I mean that seriously, but, Toluene is very unique and I can go on for hours about this uniqueness - but it is also totally unrelated to the subject matter at hand. Forgive me again! To say that epoxidized soybean oil is very stable is again one of the most ridiculous statements made. It decomposes RAPIDLY when exposed to sunlight or light at and near the UV spectrum. That is why it is used and advertised as biodegradable because it is very much so. A mere 15 minutes exposure to sun light initiates a decomposition process that can not be abated. When I developed the Formulation I presented, I had to take many matters into consideration. One matter that is completely overlooked is the number of "Vinyl Formulations" and the additives for the formulations. A very important matter is the assumption of a "typical formulation". Many people would be surprised if I tell them that I had to consider Hundreds of formulations. Yes hundreds, and I am only considering the basics. Most people do not realize during certain periods from around 1950 to 1990 the main ingredient of "vinyl records" were, in fact, Polystyrenes - yes, it’s true your "vinyl recordings" were actually "polystyrene recordings". Not that they were ever called that but that was the case. So, I also needed to consider what affected various polystyrenes based on the criteria "do no harm". Many of you have "vinyl records" that are actually "polystyrene records", and, do not think that this is a small number. It is possible that half of your collections are in fact polystyrene. Much has to do with your choice in music. much with your favorite labels, much had to do with the time period. Many recordings were for all intents and purposes polystyrene. Many others contained varying additions of polystyrene. Besides your personal selections, in some cases, it was beyond your control (that is, if you were even aware of this situation). The primary reason for incorporating polystyrene had to do with what we in the industry refer to as "Feedstocks". Feedstocks relate to the most basic of materials available and in use. It also has to do with the location of the feedstock, and, let us not forget "Politics" one of the greatest disrupters of all to the chemical and plastics industries. In the 1970’s and the 1980’s many records had no choice but to contain varying amounts of polystyrene due to the oil embargoes. I can go on forever about this subject because it affected all in the chemical and plastics industries. I suggest if you have any specific questions please forward them to me and I will do my best to answer your specific question. Examples, such as why did my Simon & Garfunkel album I purchased in 1970 sounds terrible, or wore out quickly, or competed with "Rice Krispies" on the "snap crackle and pop" sounds, while other releases were just perfect. Perhaps you blamed your stylus or your cartridge. I do know some details and particulars, but, please recall I am a Chemist, a Polyurethane Chemist. But in this matter I think that is the best way to proceed. Also, I would like you to know that I mentioned that we started our own polyurethane manufacturing facility. We eventually grew and occupied 96,000 square feet, and the business, as most businesses, evolved. Sometimes by choice, sometimes by accident. Never did I imagine that I would be asked to make thermoplastic polyurethane pellets for injection molding equipment. But two companies I knew very well and trusted propositioned us to do just that. This happened in just our 9th year in business. One guaranteed to purchase 5 million pounds per year for five years. The other committed themselves to 1 million pounds per year also for five years. In actuality the one committed to 5 million pounds per year averaged 6.75 million pounds per year. The other took about 2.1 million pounds per year. And they continued to purchase well beyond the original 5 year commitments. Those of you not in Business, this is very significant. We also later established a few smaller customers without any commitments and we also agreed to make some non-polyurethane products for some of our other key customers. This required that I needed to purchase two Bausano twin screw compounding extruders with 5 station temperature control, and with Face-cut Pelletizers that filled product at -40 degrees dew point. "Super cool machines". Nothing against Krauss-Maffei but I preferred the transmissions on the Bausanos and the lower price. At $674,000 per machine, we started with two but quickly added one more, this did not include all the support equipment necessary, just the main toys themselves. I mention this because as time went buy and things changed, we knew we were going to loose a key account because they were being purchased. Now we had over capacity in this area, so I took on what in the Industry is called "toll processing". We were approached by two resellers of vinyl formulations to high end record making companies. So we made over 3.25 million pounds of product for the recording industry in a two and a half year period. We produced eleven different formulations that were their’s and to there specifications. Actually way beyond their expectations, because it is one matter to have a formula, but it is another matter about the process and equipment used. Using the Bausano to make their product is very different than what the industry normally uses. It is like going shopping in a Ferrari versus a Toyota Corolla. Nevertheless they wherever pleased. This was just before my wife and I decided to retire. I have no idea what is happening now nor do we care any longer. The Governments made matters very frustrating and we could no longer tolerate their interference. I am mentioning this only for the purpose to avoid discussions about anything that I claim to know about "vinyl formulations". I just wanted to "nip it in the bud" so to speak. So, unless you also produced about 3 million pounds of compound for the recording industry, please know what you are talking about before making any posts, especially if you read a "tidbit" inWikipedia. However, I do welcome any questions. My desire is to share the scientific knowledge with you all. And, I do not wish to be interrupted by those who are not as knowledgeable as they think they are. It is now up to you. I do not need to do this, but, I sincerely wish to share my knowledge in other areas not just cleaning records. I want to listen to records not devote my life to cleaning them. I what to explain my position about ultrasonics without discussing ultrasonics. I would like to discuss lubricants and dampeners. I would like to provide the results about my extensive study in record mat materials. And so on, but, I need your help and assistance. You can not continue to entertain nonsense. I revealed a company that was a con. Instead of agreeing or expressing any gratitude, I had an individual defending these corrupt practices. Again, I require your support. One last thing before I sign off. And, as a Polyurethane Chemist and Polyurethane Promoter you may not appreciate how difficult this is for me to say. I believe all LP recordings should be made of Polyimides and this should be done as soon as possible. The benefits are enormous, but the outcome is far better than most of you can imagine. I wish to share my knowledge and continue this Forum. But, ultimately you will make that determination. With your approval and assistance it will be very meaningful for many. As I stated I require your conviction and assistance.

Thank you for listening!

|

Like I said, psychology is a powerful complicating factor especially when it comes to subtle differences. I just started using a new formulation with very small amounts of Tergitol and BAK, much less than I was using before. So far the stylus has remained clean. I hate to tell you this but the ethanol destroyed the seal in the water pump of my machine with obvious results. I took it apart, dried it out and fashioned a new seal with spicket packing. We are back in business. I also have a spare pump but I hate to use it. I exposed the packing to 150 proof ethanol and it dissolved. I have to reformulate. Any Suggestions? I switched back to Isopropyl 10% and increased the Tergitol to 4 drops plus 2 drops BAK which kills the static even at this low concentration. |

The residue that was on the record was at levels below visually detectable. The general rules of thumb are a person with unmagnified 20:20 vision can under bright white light (100-foot candle source positioned 18" above the surface) see a 50-micron particle while with intense UV (assuming the film/particle is fluorescent) can see 25-35-micron depending on the UV light source. Industrial UV inspections lamps can be 100W (and can could damage the record) while what was used was 10W. However, once the UV dye was rehydrated and dissolved by the rinse water, and being effective at "ppb's", the rinse water covering the surface the record becomes easily detected.

The quantity of Tergitol 15-S-7 you are using is 38 mg/L, which is the same as 0.038 mg/ml. If you leave behind 1-ml, 0.038-mg uniformly spread across the record will yield a uniform film thickness of about 0.0038-microns. This is below the best info I can find the record surface roughness of 0.01-micron which is smoother than a #8 Super Mirror Finish/Non-Directional Mirror Finish used to produce/polish stainless steel mirrors. If the Tergitol 15-S-7 did provide a lubricant effect, then you should also believe that the LAST treatment works. The LAST treatment as @wizzzard elaborated being nothing more than a perfluorinated oil (such as Fomblin Y45 datasheet.aspx (ulprospector.com)) dissolved in in a fluorinated solvent, the solvent evaporates leaving behind an oil film. Now all nonionic surfactants are somewhat hydroscopic, but they pale in comparison to the hydroscopic nature of the cationic surfactant BAK-50 that you use as an external anti-static. Note that RCA developed an internal cationic anti-static record composition over 60-years ago G. P. Humfeld, Anti-Static Phonograph Records, RCA Engineer Magazine Vol. 6, No.3. October-November, 1960 1960-10-11.pdf (worldradiohistory.com). Given the complexity of coating the pellets, and the experiences with modern pressings, I doubt that this internal anti-static treatment is much in use today. As far as 'why' your records have a lower background noise - you never indicated the composition/concentration of what your cleaner was, but you earlier indicated that detritus was periodically building up on your stylus - is that still the case? If not, you may have your answer. Any detritus that builds up on a stylus can have profound effects on playback beyond the simple background noise. Read this article - STYLUS MASS AND DISTORTION, by J. WALTON, Wireless World, April 1963, Wireless-World-1963-04.pdf (worldradiohistory.com). Take care, |

My experience with the Loricraft, when compared to the VPI 16.5, is that it does a better job of drying the record, and presumably removing dissolved cleaning chemicals. While I am currently experimenting with pure DW in a Degritter afterwards, I am not noticing any tendency to foaming, even towards the end of twenty records, at which time I change the water. |

I think there is way too much variation between vacuum machines to make a blanket statement. I'm a bit confused. You said the record did not fluoresce but the rinse water did. The stuff that did not fluoresce on the record now fluoresces in the rinse water. I'm having trouble with that. My goal is to remove all the debris and contamination from the record. It is not to not leave a residue. As a matter of fact I want to leave a very small residue to combat static. The Tergitol is like water soluble oil. It is slippery stuff. This may be psychological but it seems to me that the background noise present in all records is quieter after cleaning and I question a lubricant effect. |

@wizzzard Thank You for your recommending a method for producing a solution, that can be used as a alternative to my already in use PAVCR recommended solution, for the successfully used Manual Cleaning Method. I will be considering this alternative mixture for the BASF Dehypon LS 54, and will work out the best method for myself to determine if there is more to be attained over a already tried and tested method, that has yielded substantial improvements over all other cleaning methods used.

I don’t see the need to be concerned that Tergitol S7 or Lutensol® LA 60 are not readily available. It does seem Neil Antin has found the substance that is readily available in the UK. |

The records were dried enough to leave the record dry without static. However, I suspect you are misunderstanding what I was trying to say. So, let me rephrase this mathematically. If 5-ml of cleaner was applied to the record, 4-ml was sucked up from the record and 1-ml was dried in-place. After cleaning and vacuuming the records were dry with no visible residue under white light or UV light. However, when DIW rinse water was then applied, the rinse water quickly fluoresced. After vacuuming if the 1st rinse fluoresced, rinse water was applied a 2nd time to see if it continued to fluoresce. If not, then the surface was assumed residue free. For some high concentrations of cleaner that were used, two rinses were required to achieve a residue free surface. For all tests, the quantity of cleaner and rinse water applied was measured out and the concentration of cleaner (& dye) was known. If there is ever a 4th Ed of book, the full details will be described in Chapter XIII that discusses vacuum RCM. Otherwise as always use this info as you see fit. FWIW: I do not believe the point-source vacuum RCM such as the Monks with small tip (no large lip) and much higher vacuum and much less are air flow would behave the same. I suspect that their ability/efficiency to draw/suck-up fluid from the record is much higher but only actual testing would confirm. |

The VPI RCMs may be relatively crude looking, and the vacuum motors may make a lot of noise (mine does), but one cannot complain about a product that has worked flawlessly for more than 25 years, most of the time holding mildly corrosive liquids in its two tanks. The HW17's vacuum motor not only still works but remains "very powerful". (Data that were missing not only from my foregoing statement but also from the above assertion that vacuum cleaning leaves 10 or 20% of the original moisture on the LP: power of the vacuum, time spent under vacuum, etc.) |

@antinn |

@mijostyn |

@antinn , Great dissertation on Ultrasonic cleaning, Thanx! Finally got the Tergitol. I could only get 150 proof ethanol so I had to mix the formula by the seat of my pants. It works fine in my machine, spreads out over the record perfectly and when we run out of Vodka we have another option:-) |

FWIW: The benefit of the nonionic surfactant Tergitols 15-S-7 & 15-S-9 are their very high performance as compared to the older Triton X100. -Surface tension of the water is ~72 dynes/cm. -Surface tension of the record is ~37 dynes/cm. -10 ppm (0.001%) Tergitol 15-S-9 reduces the surface tension of water to ~45 dynes/cm. -20 ppm (0.002%) Tergitol 15-S-9 reduces the surface tension of water to ~37 dynes/cm. This is enough to quickly 'wet' the record. For UT cleaning, wetting the record has the advantage that water runs off the record and does not bead-up on the record significantly quickening the drying time. Drops take a long time to evaporate. -52 ppm (0.0052%) Tergitol 15-S-9 reduces the surface tension of water to ~30 dynes/cm. Adding anymore will not lower the surface tension any further and is known as the critical micelle concentration (CMC) and at >52 ppm, and you begin to get detergency. -3X to 5X CMC will give the full detergency that the surfactant can give. The CMC for Tergitol 15-S-7 is 38 ppm and the resultant surface tension is 28 dynes/cm. The CMC for Triton X100 is 189 ppm, and the resultant surface tension is 33 dynes/cm. For surfactant residue (assuming specific gravity of 1.0 for ease of use), a simple thumb rule is 1-mg of residue uniformly applied to the record surface will yield a residue film thickness of 0.1-micron. From my research, the surface roughness of the record is about 0.01-micron and smallest recorded modulation is 0.1-micron (high frequencies). From working with people across the globe in setting up record cleaning processes, the threshold for hearing soft 'viscous' nonionic surfactant residue is about 0.03-micron or 0.3-mg and it's noticed as a dulling of the high frequencies. Everyone's threshold of hearing residue is different based on physiological differences in hearing sensitivity as well as the playback system and the person's experience. There is the obvious point when the residue is so high that it is now apparent on the stylus. The big benefit of the Tergitols (15-S-7 & 15-S-9) over Triton X100 is that much less is needed, so the risk of audible residue is less. Triton X100 should not be used w/o a rinse step. This last Xmas I worked with someone in the UK, and we did a qualitative study of the vacuum efficiency of a German made high quality blower-style vacuum-RCM, similar to VPI. Cleaners of known concentration were spiked with a high-performance UV dye (sensitivity in the ppb). The vacuum-RCM was only on average 80% efficient in removing all fluid from the record. About 20% was evaporated in-place. For vacuum-RCM, if using a cleaner with high concentrations of surfactant (>50 ppm), at least one post rinse is recommended. |

As mentioned several times above, I have been using 25% IPA in water plus about 0.1% Triton X100 for many years before now. About 10-15 years ago, I started to worry whether the mixture left an undesirable residue on my LPs, even after vacuum drying (not air drying) on my VPI HW17. I then instituted a rinse with pure deionized distilled water, to follow vacuum drying after the initial cleaning with the above solution. I had and still have the distinct impression that the pure water rinse makes a very audible difference in the positive direction. I think, back when this happened, my experiment was to clean both sides of one LP and follow up with water rinsing only one side of that LP. Then I listened to both sides. Results were in favor of the water rinse, decidedly, and I haven’t looked back. |

The amount of Tergitol is so slight that rinsing would be an unnecessary step. It is also very soluble and will dissolve into the next cleaning. It will not build up on the record. |

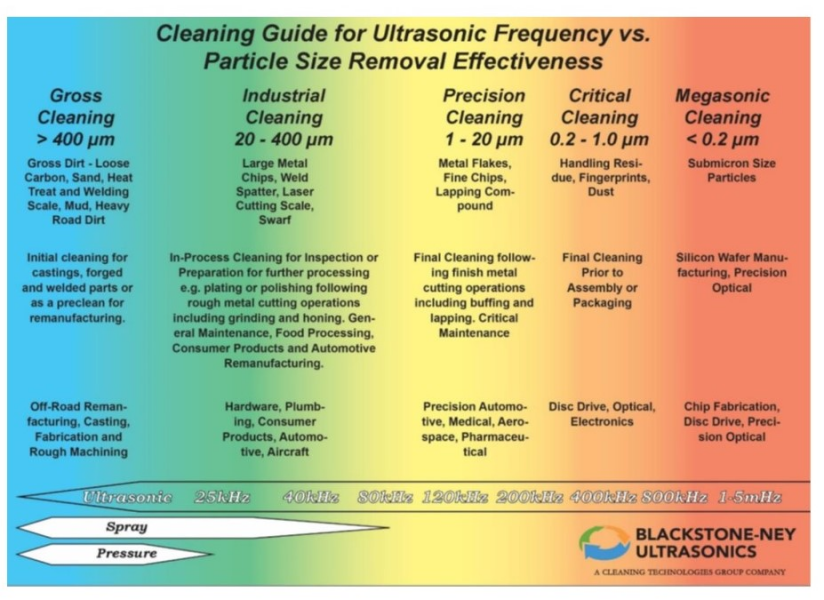

Interesting thread. Didn't read every single entry but have a few comments. The Very Best uses Ethanol which commercial cleaners avoid. I assume that this have to do with alcohol regulations around the country. The function of Ethanol in the cleaner is a solvent to remove any greasy contamination on the record. Water is also a solvent but not as efficient for some types of contaminants. Both distilled water and ethanol evaporates without leaving a trace on the vinyl - very good. 20% Ethanol also lowers the surface tension of water from 72 to 39. Adding surfactant reduces the surface tension further and helps get the liquid into the groves. Question is if Tergitol 15-S-7 leaves any residue behind on the record surface? Does anyone know? If Tergitol has high solubility it may be removed with final a wash of distilled water or Water-Ethanol mix. (Perhaps we should use distilled water with some Ethanol added as our standard final rinse? It might dry faster than just water and the lower surface tension should make it easier to remove with a vacuum machine.) Lots of details on Ultrasonic cleaning has been reported in this thread. It appears that should be possible to design an optimized machine for USC of vinyl records. What bothers me is the extremely long time required for cleaning. An optimized cleaner would clean the record in a single revolution! One bubble collapsing will perfectly clean that spot. So the commercial machines rely on some random cleaning and longer times increase the probability that a high percent of the surface gets impacted. Perhaps longer times also helps with regular cleaning by diffusion. I had a few records USC by others and they sound better (subjectively). Thinking about getting a variable frequency tank with an LP attachment. The automated machines like Audio Desk would be more convenient. With the information in this thread it gets more confusing as commercial machines use different frequencies. Haven't found any direct comparison testing. Would it be hard to clean identical LPs and then record the spectrum?

|

I think most of us on the forum just want to enjoy listening to music. Any recommendations to help us along our musical journey are always welcome. I hope you are able to enjoy listening to music as well. There’s no need to get overwhelmed by anything on these forums, but I suppose if you get overwhelmed by anything, it’s best to be overwhelmed by good music! I can recommend Chopin’s Nocturnes played by Claudio Arrau for starters. Enjoy! |

The discourse with using Hansen solubility parameters is not unknown - Hansen solubility parameter - Wikipedia. My use of it within this forum was only as a prediction. If your feelings on this subject are so intense, you have a possible avenue through Wikipedia to set the story straight if it needs to be. However, not to cause you any further grief, you may wish to check the math on the drops. Drops can be 0.04 to 0.06 ml each (for those reading 1-ml water = 1-g). I like the Nalgene Dropper Bottle that delivers a fairly accurate 0.04-ml/drop - Factors to consider in accuracy and precision of Nalgene Dropper Bottles (thermofisher.com). Peace |

Dear Wizzzard , I am very sorry that you are plagued by your illness. I wish you well, and I also hope your wife will soon conquer her medical problems. As for me, I release you from any perceived obligation to respond to any of my real or imagined questions. Probably, when the effects of your affliction and the medications you are obliged to take in order to combat it are stripped away, you are a very decent chap. At the moment, however, we should not take this any further. The odd part is I haven’t disagreed with anything you wrote as regards chemistry or record cleaning solutions. Carry on. |

My reference for a concern was an open top UT tank with 6000-ml and larger volume. Your HG contains 350-ml in a mostly closed tank. Ask the manufacturer who is very responsive to requests what they think. Beyond flammability that unit uses a lot of plastic that may not be compatible with the alcohol. |

Yes, I was prepared to respond to you with one of my surly statements again, especially after you, did not disappoint me, and was able to inform me of what my personal thoughts that kept reappearing in my mind actually were. Of course I knew that the Captain played by Strother Martin while standing on the ridge said ""what we have here is a failure to communicate". However I included the (BANG) after the quote to relate when it is REPEATED by Paul Newman just before he is killed, is more significant and relevant to the entire story. Plus, and a very important plus, they were MY THOUGHTS. How insightful of you. But I chose not to post my prepared scathing remarks. Especially after I had witnessed a possible glimmer of hope. Although, the remark was in parenthesis by you [ Despite Wizzzard's antagonistic attitude toward my posts, I may change the formula thanks to him.]. You need to go back in time to the very beginnings of time to review who was "antagonistic first", in fact "the antagonism" started before I even made any statements. But, because of that "possibility and glimmer" I will forgo my prepared statement and "make you an offer you can't refuse". Actually you can refuse but perhaps you should not. Now, you stated what you use volumetrically, and I would hope you can convert that to parts by weight for better precision. you, however, never mentioned how much Triton X-100 you use in your formulation. Everything else is now known. Allow me to state (in may terms) your formulation. Deionized Water. 803.650 grams Isopropyl Alcohol (98.0%). 196.350 grams Triton X-100 ?.??? grams Total Weight 1,000.00+. grams

Now, if you slightly lower the amount of Isopropyl Alcohol and use the correct amount of Triton X-100, the formulation would be as follows:

Deionized Water. 804.772. grams Isopropyl Alcohol (98.0%). 195.000. grams Triton X-100 0.228. grams ( Approx. 11 to 12 drops) Total Weight: 1,000.000. grams

Now, go ahead," just for the heck of it", compare the above to the following. It won't kill you. Deionized Water 779.772 grams Ethanol (99.5%) 220.000. grams Triton X-100 0.228. grams. (Approx. 11 to 12 drops) Total Weight: 1,000.000. grams Also keep in mine that 12 drops is better, but do not add more, the reasoning behind the 11 to 12 drops, original suggestion. Use it as you would normally. We now know that we both have VPI HW-17 Record Cleaners. And they are of about the same time period. Another thing I did manage to recall. Was that when my unit was given to me by the individual that I purchased a lot of other equipment from, also provided me with a bottle of "VPI Record cleaner. The bottle was about 500 cc, I have no idea as to what the surfactants or additives (if any) were, but, I distinctly remember without any doubt, that it contained Ethanol as well as water. Also, there was no trace whatsoever of any Isopropyl Alcohol. I can assure you I have a very "good nose" for solvents. Others jokingly use to say ask Wizzzard to do a "Finger Chromatography". Which I did, and, surprised many people by not only the content but the percentage. What can I say, it was a "Gift"! If you agree to perform this simple test, regardless of the results you provide me, I promise to tell you all the details of as to why Ethanol and not Isopropyl Alcohol. More detail than you will ever want to know. This is so that you do not have to embarrass yourself to thank someone for a "non-answer"- "answer". And, I will be kind up front so you need not to bother "doing a deep dive" into Hansen's 519 page book. The answer is not in there. I did not think so, but, just to be certain I went through my Complimentary Edition that I have in my Library. Yes, I did say that correctly, my Complimentary Second Edition . You see CRC Press made an offer to me many years ago, and I still receive Various Books at no charge even though the company has changed hands many times. I only stated this because I would not waste any money purchasing that insult to Dr. Joel Henry Hildebrand, with whom I had the pleasure, and honor, to collaborate with many, many years ago for about 6 months. One of the greatest Chemists this Country has ever known. And one of my greatest experiences as well. He received every distinction and award possible, with the exception of the Nobel Prize, which he was worthy of as well. And, as for Hansen in his Phd. Thesis to do a terrible injustice to SORRY, I have to stop , I am getting very emotional and annoyed right now, you can't imagine. I am sorry I will need to leave you now. please consider what I offered. Perhaps when I cool off I can explain myself better to you. I have to go!

|

@wizzzard Thank you for the detailed reply. I do think I grasp some of the significance, reading back through the thread. As for the UltraSonic cleaner I have, it is the HumminGuru. And with regard to minds exploding—and rooms exploding—I'm not sure what to think. For you, not a concern. For @antinn it seems to be a big concern. |

You can say what you wish, but the law (29 CFR 1910.106) is very specific as to what is classified as flammable - NFPA_30_Fact_Sheet_2021.ashx. And, in larger volumes, in small spaces, flammable vapors can be build up - NFPA Journal - Safe Distilling, Mar Apr 2018. Yes, as you have implied the flame speed and heat of combustion of water alcohol solutions are low, but the minimum ignition energy is well within the range of a 120V electrical contact. But are you familiar with what is now available for ultrasonic tanks - Amazon.com: VEVOR Ultrasonic Vinyl Record Cleaner 6L 40kHz Vinyl Ultrasonic Cleaning Machine Knob Control Record Ultrasonic Cleaner 4 Records Vinyl Sonic Cleaner Stainless Steel Tank w/Mechanical Heater & Timer : Industrial & Scientific. Do you think these low-cost PRC manufactured UT tanks are UL listed? You have no idea of people’s domestic use situation. Some people put these low-cost UT tanks in closets or small bathrooms (w/o venting) because they are so noisy. I have education in fire science and I have firefighting training from when I was in the Navy, and I would not make any general recommendation for use of any fluid in larger quantities such as in a UT tank that the law classifies as flammable, without a whole lot of caveats, and I suspect that the NFPA would not even think that was safe. But that is me, and of course you and anyone reading is free to take exception. And with this being said, I have nothing else to say. |

I apologize I have been away for a few days and was unable to post. Also, My new computer appears to be very problematic, and it is driving me crazy. I noticed that this is your very first post - and what a post it is (although you may not understand the significance that I am relating to). Noting the "unnecessary back and forth", and asking for answers to what would normally appear to be simple and straightforward matters. Not realizing that my answers to you will rupture the brain vessels of several of the contributors to this Forum. Nevertheless, you can obtain Tergitol 15-S-7 (now a Dow Chemical Product) on the internet from: a.) "The Lab Depot", or, b.) "Advance Scientific & Chemical", or, by contacting (by phone) a local Dow Representative or Dow Chemical Distributor. There are other internet choices, but you will need to do your own searches. Phoning a Dow Representative or Distributor may be very productive, however, unfortunately it has a lot to do with where you reside. Remember when speaking to any of these individuals to be truthful and honest with regard to your intentions, and your interest in the product. You may be pleasantly surprised, or, not! The answer to your second question is that YES it can be used in an Ultrasonic Cleaning device, but, recall your times in the bath may only be one-tenth of a "normal" time period, and that no rinsing (especially with distilled or deionized water is required or recommended. It is self-defeating in many respects. If you feel compelled the "rinse" then rinse only with the formulation that is presented. Before I say more, I would ask of you to first respond if you already have an Ultrasonic Cleaning device or not? Get back to me about this, and it can be further discussed. This is where I already sense that other contributors minds are "blowing up" (yes, pun intended). You may understand at some point as to my referrals, and, if and when you do, you can then explain it to me. Recall, my "Very best Record Cleaning Formulation" is just that, and it is to be "an ease of use" product as well. Good Luck, and keep in touch! Wizzzard |

cleeds, Now I am a bit confused. Above, you wrote, "As I mentioned @lewm , I use a Klaudio US cleaner and have a conventional OG Nitty-Gritty. I don’t find that either cleaner requires alcohol to remove common contaminants." Here you are saying you do use a solution with a water base (e.g., the VPI RCM concoction, whatever that may be) with your NG. If so, we are in accord. My earlier point was that US RCMs don't or certainly may not require anything but water in the tank because of the very nature of how US works. Whereas, I mentioned I do use a water plus alcohol plus nonionic detergent solution with my VPI HW17. So, no problem. |

cleeds, Have you really experimented with mixtures such as the one recommended by Wizzzard, for your Nitty Gritty, and compared such a mixture with plain water? If you find no difference between the two, using the NG, then I am surprised. And can only say good for you, or something like that. I have no US RCM. I use a VPI HW17, and have done for the past 25 years at least. My go-to mixture has been distilled deionized water plus IPA plus Triton X100. (Despite Wizzzard's antagonistic attitude toward my posts, I may change the formula thanks to him.) I do find a big improvement with that solution vs water only. I do buy mostly used LPs, but my standards for purchase are very high. I only buy LPs that appear perfect to my visual inspection and/or are "A" rated by the seller, and I really only buy from one local vendor who has been reliable or from Disc Union, in Tokyo, on occasions when we are visiting our son who lives there. Which is to say I don't buy junk from Goodwill or sight unseen off eBay. And yet the alcohol and nonionic detergent containing solution obviously works better than plain water. I do also rinse with plain distilled water after the first wash cycle. That clearly makes a difference too. |

I used a VPI 16.5 since 1981 (with 28,500 LPs and 7,000 78s). Various solutions were used including one which used ethyl alcohol for LPs as well. Lastly Disc Doctor. Then I began using the Kirmuss US with drying in the VPI. With many used LPs, I found that the sound was uniformly enhanced using just water and/or the water/alcohol solution. HOWEVER, what is revealed on some used LPs is noise and damage that was done. So, previous debris covered divits or other imperfections are now exposed and make more noise. Overall, I love using it and most of my LPs are just quieter with enhanced sound. |

@lewm, The KL Audio is 40kHz, with four 50W horizontally positioned transducers, two each side (200W total) with a UT tank volume of only about 0.78L - that is it's a very powerful machine. Note that the reservoir is 2.4L, but someone recently measured the change in reservoir volume to fill the unit - ergo the UT tank volume. With the very small volume and amount of power available, it does not need any enhancement with chemistry. Here is a quick summary of UT concepts and some basic thumb rules: Ultrasonic tanks 'grow' bubbles Principle-of-ultrasound-cavitation-16-The-initiated-bubbles-grow-due-to-evaporation.png (850×553) (researchgate.net) until the bubble collapses. Watch this video between 6:19 and 8:30 Cavitation - Easily explained! - Bing video to see how the bubble collapses. Here are the basic thumb rules for ultrasonic tanks: -The power to produce cavitation is proportional to the kHz, so a 120kHz UT needs more power than a 40kHz. For records, in general, the most difficult items to clean/remove are particulate. The paper Adhesion and Removal of Fine Particles on Surfaces, Aerosol Science and Technology, M. B. Ranade, 1987 (Adhesion and Removal of Fine Particles on Surfaces: Aerosol Science and Technology: Vol 7, No 2 (tandfonline.com) shows for aluminum oxide particles, the force (acceleration) required to remove a 10-micron particle is 4.5 x 10^4 g’s, a 1-micron particle is 4.5 x 10^6 g’s and a 0.1-micron particle is 4.5 x 10^8 g’s. A simple brush or wipe is not going to get the smallest particles/debris that can ‘hide’ in the valleys between the groove side wall ridges. As fluid flows past a surface, a boundary layer is developed and depending on its thickness (upwards of 5 microns) it will essentially shield any particles within it. So, agitation is critical in reducing the boundary layer to expose the surface with its particles to the cleaning fluid and the fluid velocity (shear force) that can remove them.

-The boundary layer thickness is dependent on the ultrasonic frequency (high kHz = thinner boundary layer), acoustic energy, and fluid properties (viscosity & density). To get the most effective cleaning, the complete cleaning process has to penetrate the boundary layer to remove the soil and particles that are contained within it. At 40-kHz, the boundary layer 'can' be as thick as 5 microns, while at 120-kHz, the boundary layer 'can' be as thin as 2 microns. -But there is a delicate balance with using chemistry and UT that can improve the cleaning efficiency more than the small expense to the cavitation intensity (more an issue with low power units). But use too much chemistry or the wrong chemistry and it's all downhill. There is an entire science about particle adhesion and removal and if you wish to entertain yourself here is a good book to start with - Particle Adhesion and Removal | Wiley Online Books. Beyond all this, if you are going to get into an academic discussion on record cleaning, there is the existential question of just how clean a record needs to be to provide maximum playback fidelity? From my research, the answer is quite complex and a topic unto itself. But absent the details, people default to trial and error, and what they hear. Which is perfectly acceptable, and which is why when someone asks me what is best, I will always say, what is best for you. Now back to the regular scheduled programming. |

@lewm , I totally agree with your hobby argument. I also think I continue with vinyl because it is so imbedded in my head. One of the happiest events in my childhood was getting a new record. As a teen I would spend hours in record stores flipping through records. I do not get the same rush buying online. I find your "do not want to be bothered," argument a bit silly. Digital is EASY, it is vinyl that is a PITA. You can load a playlist and not have to touch the system all day. I can send music all over the house, the shop in particular. Running up and down stairs every twenty minutes while I am working on a piece would be a real PITA. You don't have to worry about being screwed with a defective $10,000 cartridge (more on that in another post.) |

As I mentioned @lewm , I use a Klaudio US cleaner and have a conventional OG Nitty-Gritty. I don’t find that either cleaner requires alcohol to remove common contaminants. Hence my question that no one has answered: What has contaminated these LPs that alcohol is required for removal? Or, are you guys just having fun experimenting and mixing various solutions? |

cleeds, You are apparently using an Ultra Sonic RCM. That’s a completely different approach from using a conventional RCM that relies upon "scrubbing" using a solution that can solubilize typical contaminants and which makes the water wetter to facilitate deep cleaning. In a US cleaner, the ultrasound itself (ideally) does what the additives do in a conventional RCM. ljgerens said it best. So, yes, you don’t necessarily need alcohol in your US RCM. |

I did something different today with a 1979 LP (new to me). I used AI Enzymatic formula on the Loricraft and then just distilled water in the Degritter. I did this because the record looked dirty (and had a superficial scratch on one side). Came out silent - even the scratch was not audible, though the cleaning can't take credit for that. I'm impressed with the Enzymatic formula and have saved it so far for my dirtiest finds. It really is good, and maybe, if I were feeling flush, I would substitute it for my usual PhotoFlo/ethanol/DW mix in the Loricraft. |

You are correct regarding the effectiveness of distilled or deionized water be itself in the ultrasonic bath. Refer to my post on 06-21-2023 at 4:05pm. i don’t know whether there is a right frequency or wattage but my experiments @ 40 kHz demonstrate that water alone in the bath is very effective in most cases. |