I'm am beginning the process of building a new house and I have been researching this topic over the last year. As you have likely figured out from this thread, there is no consensus about the best practices for electrical design for an audio system and a couple of my comments are in conflict with earlier responses, but here goes.

First of all I highly recommend reviewing the articles and videos from Michael Fremer regarding his electrical power experience. The links are: Fremer Electrical Video and Analog Corner Power.

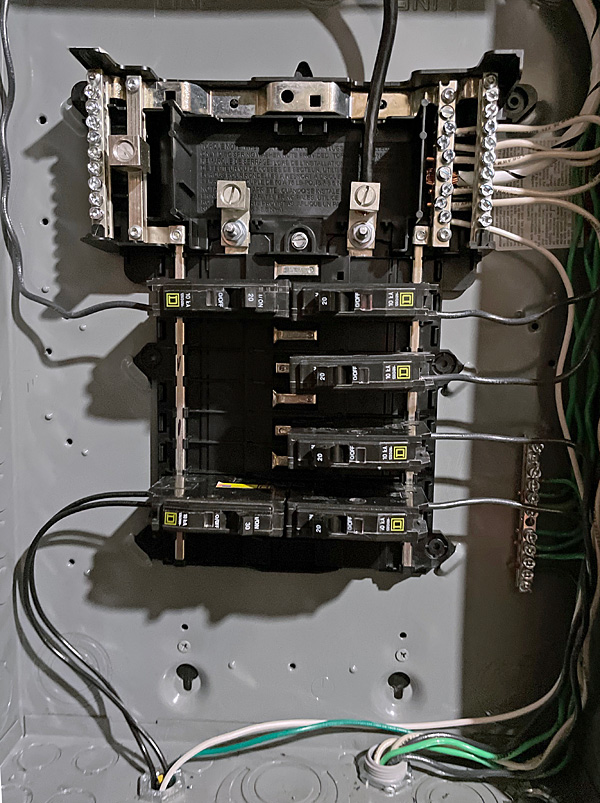

Separate Audio Panel - I'm going to use the system from AudioUltra (Seattle) AudioUltra for a separate panel for my stereo room. This is fairly expensive but it's not too bad for new construction. I met both the Kingrex people and the AudioUltra people at last year's Pacific Audio Fest (they had separate booths/rooms) and I believe that they make their own panels. I talked to Rex Hungerford for quite a while and I came away with the impression that he is catering to folks that are a whole nuther level of OCD about their systems than I am. The guy from AudioUlta (I think it was DeVito) was much more down to earth and more my speed.

BTW - There are no heroic features to my current electrical setup and my system sounds outstanding. I do run a dedicated 20 amp circuit for my Krell KSA300S but the other gear is on a shared 15 amp circuit.

10 gauge wire - I've been told by several experienced people that for typical run lengths 10 gauge wire will not provide any benefits over 12 gauge. The only benefit you might receive from 10 gauge is if you have a very long run and the 10 gauge might present a slightly lower voltage drop. In my case my panel will be quite close to my outlets so I'm going with 12 gauge wire and 20 amp outlets.

Special outlets - I met Caelin Gabriel from Shunyata at the 2019 AXPONA during a slow period in the room and he was very friendly and generous with his time. The subject of electrical outlets came up and he told me that hospital grade outlets were not suitable for audio use. They are made from stainless steel and are designed to prevent corrosion from the strong cleaning chemicals that a hospital uses. They do not transfer electricity as good as a copper outlet. He said to only use outlets with copper hardware and he said that for a reasonable cost the best outlets are made by Hubbel such as the HBL5623W for 20 amp outlets. I took his advice and replaced my 20 amp outlet with this model. I don't think I heard any difference but it makes me happy.

I'm fortunate that we have our own transformer which is right next to the new house so our incoming power should be excellent. I am not going to go with any kind of power supply filtering or processing between the transformer, panel, and the outlets. I have tried a couple of power conditioners in my present setup and I have not heard a noticeable effect.

I'm going to have an emergency generator and I'm depending on AudioUltra to insure that I don't get the same problem that Fremer had. Having a dedicated panel for the audio room should completely solve that.

And finally, a philosophical note about electrical codes. I'm no electrician but I have had a lot of experience with construction and I have come to believe that electrical codes are carefully researched and very robust. You can have a run of about 57 feet on a 20 amp circuit (at full 20 amp draw) with an acceptable voltage drop of 3.6 volts. If you go with 10 gauge wire that goes up to about 71 feet. 10 gauge won't hurt anything but unless you've got very long runs it's doubtful that you would ever hear a difference.

Good luck and please report back on what you install and how it sounds.