Personal Experiences:

Part of a smashed kit I bought and returned: It had a UA-7045 with a bad grommet, took it apart, measured, found rubber stepped washer fix at home depot, but returned the smashed kit, never installed/used it. I would use my AT headshell with adjustable azimuth if needed, the MA505L armtube fitting is itself adjustable for azimuth

I installed a pair of MA505's long and short for a friend, took them apart, set them up, played them, I like everything about them.

|

A caution for anyone considering the MS 505. I've mentioned this elsewhere but repeat it here.

I agree with Elliot that it is a very good arm. However many used examples have damage to the stub where the counterweight is mounted. This is easy to determine, make sure the stub is in the same plane as the arm tube. Many of them sag or are slightly drooped.

There is a cushion where the stub is mounted which can deteriorate with time. That should not be overly difficult to replace unless the mounting screw is stripped. Mine was and I had to send it to a specialist for repair.

Some may claim the stub droop is original design but it is not.

|

Pryso, are you sure you are not thinking of the Victor tonearm, not the MS? The drooping counterweight on the former tonearms (7045 and 7082) has been much debated here. I would argue, and did argue that the droop is actually a potential upgrade to the original, albeit unintended, if the weight is hanging at only a shallow angle, because a perfect shallow droop would place the center of mass of the CW closer to the plane of the LP surface, which is a deliberate and desireable feature of many more modern designs. I don’t argue that the droop is part of the original design, just that it may be accidentally serendipitous. I own a 7045 that droops and did also own an MS505. I don’t recall that it too used a rubber grommet between the pivot and the CW but maybe so.

|

Many of us are aware it is the Victor 7045 and 7082 arms that have a rubber grommet, like the SME 3009 3012 arms, that isolates the rear counterweight section from behind the bearing and forward parts of the arm, and they deteriorate. SME’s concealed long tube grommet age and rot, I replaced mine with OEM part, but are harder to see, the Victor stepped grommet weakens, tears, Sag is obvious, perhaps even beneficial for a time as lewm mentions, until it further deteriorates.

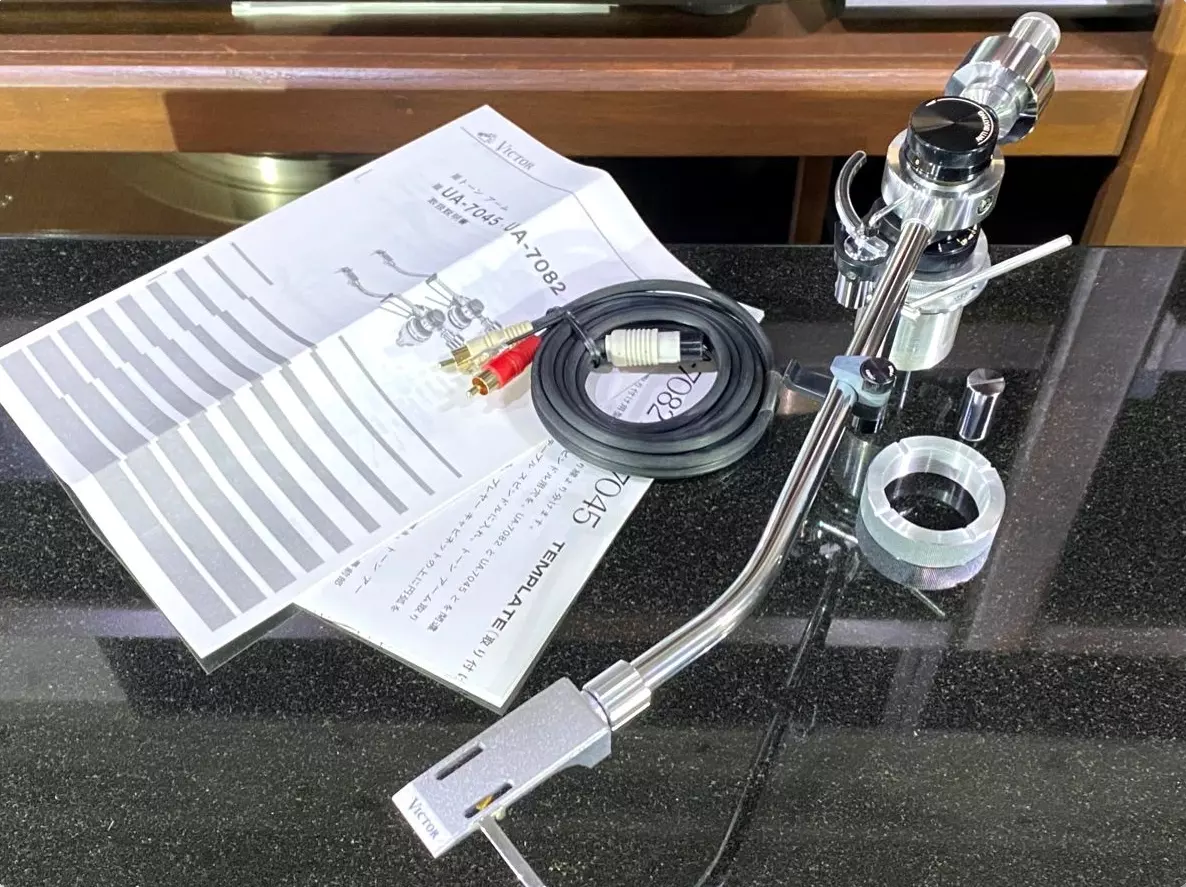

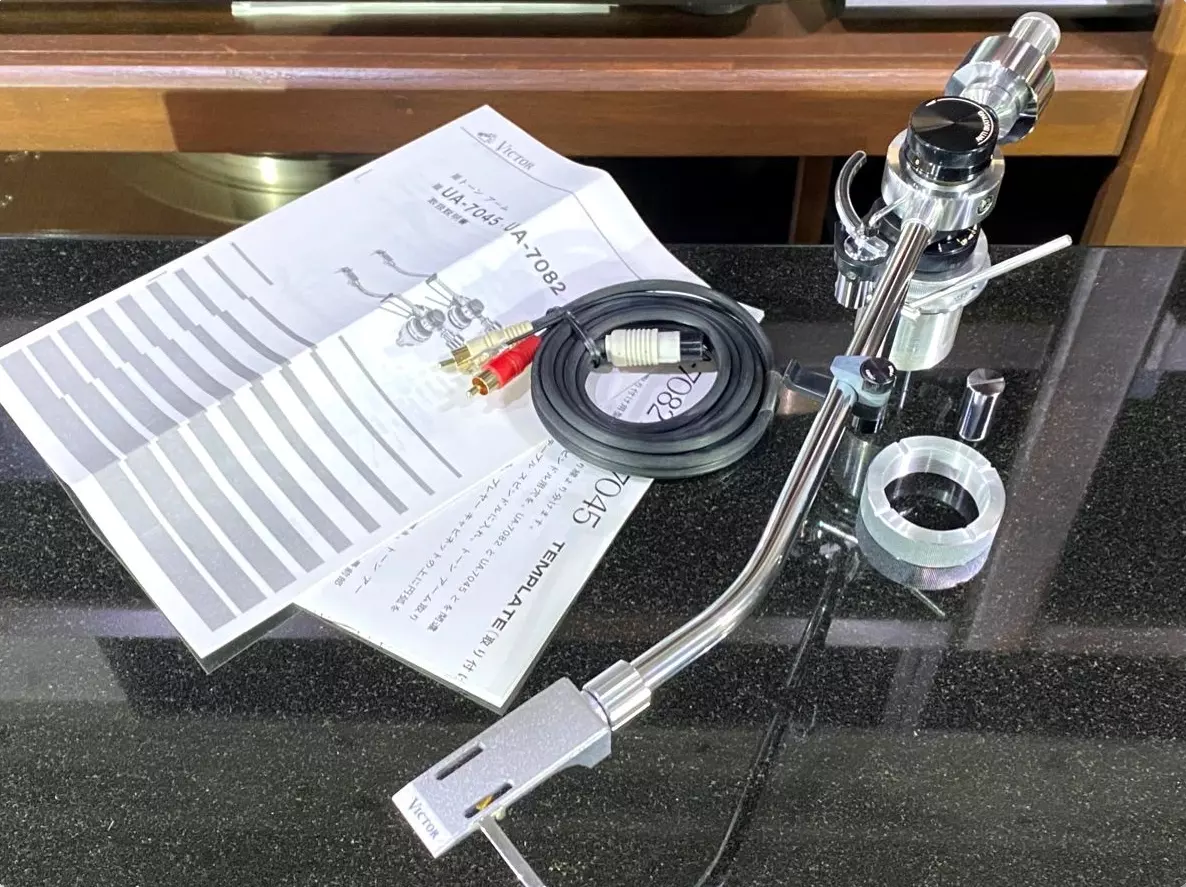

My post: Victor UA-7082 Arm (good grommet)

..............................

Aside from that, what choice would you make?

I like them both, but never installed or used the Victor Arm like I have the Micro Seiki on my friend’s Luxman PD444

|

Endless…some like Thom at Galiber would argue the isolation for CW is lossy and he modifies / markets the Jelco arm as such. He is also working, albeit w distraction ( like any good music loving audiophile ) similar mod for Triplaner.

OP … my coin flip is 505

it has been a long time since i have heard one….

|

I know this is a bit pedantic, but why stop now? The arm needs to work well with the cartridge, so I would make the best estimate of which of the two tonearms will work best with whatever cartridge you plan on using. I have no independent confirmation, but the Victor tonearm is probably medium mass and maybe so also is the MS tonearm. In this case, both will have slightly higher effective mass than their 9-inch counterparts. Have you seen any published (by Victor or MS) effective mass data for either? I have not. And of course the headshell (weight and composition) plays an important part in the match.

Tomic, the Triplanar CW is already decoupled from the pivot (not by a rubber bushing) and placed in the plane of the LP surface, so what does Thom do?

|

Without paying too much attention, my choices, I have never had resonance issues.

I will rotate several existing and future cartridges, light tracking preferred:

all at 1.25g.

AT160ML Microline/Beryllium (2nd one arrived yesterday); Shure V15Vxbody/Jico SAS/Boron; Shure 97X both OEM elliptical/aluminum and advanced stylus/boron from VAS; AT440ml Microline/Tapered Aluminum; ATTR485U Shibata, AT14Sa shibata/tapered aluminum:

at 1.5g

Grado Mono Elliptical/aluminum

my heavy trackers at 2.0g.

Sumiko Talisman S Van den Hull Line Contact on sapphire tube, AT33PTG/II Stereo MicroLinear on Boron; AT33PTG/II Mono advanced stylus/boron from VAS:

////////////////////////////////////////

adjusting these two arm choices on the Fly.

Not having mounted/used it, that is my open question on the Victor 7082, is it smooth enough to adjust height while playing. Does it unlock/lock smoothly and firmly, while playing. Adjust tracking force and anti-skate during play?

I unlock and change the Acos Lustre GST-801 arm height during play without hesitation, it is the smoothest height mechanism I ever used, I wish Acos Lustre made a long version.

I find the Micro Seiki is not as smooth, harder to have confidence it it being secure, so I lift the arm, release the lock, make an adjustment, lower the arm: both quick and easy, but not during play.

My friend’s Technics EPA-BP500 Base is easy, you simply turn it’s big base ring, no lock/unlock needed, but I am left handed, need to use my right hand, so I lift his arm, make an adjustment, lower the arm.

I have adjusted both tracking force and anti-skate on the Micro Seiki 505 while playing, not the Acos Lustre or Technics

|

I have never understood the fetish about "on the fly". I have several modern tonearms capable of adjusting VTA on the fly based on their method for adjustment, but I would never think of adjusting VTA while playing an LP, assuming that the phrase "on the fly" means just that. It's no big deal to lift the tonearm, make an adjustment, and then lower the tonearm to resume play. With no risk to cartridge or LP. On the other hand, I would not own any tonearm that still relies upon a grub screw at the base of the pillar to change arm height/VTA such that you have to secure the tonearm with one hand, loosen the screw, change the height, and then tighten the screw, all in order to change VTA.

|

It's not a fetish to ask people for their experiences, and IF it is smooth enough, it is a tremendous feature/asset. I just want to know what others here have found.

I am asking if anyone has personal experience with either of these 2 arms, and letting you know what my experiences with the few arms I have messed with.

does the Victor arm height mechanism feel secure when you lock it? has anyone found they can adjust tracking and/or anti-skate during play?

|

OK, seems nobody currently using these two arms.

maybe a different approach:

What Long Arm with Removable Headshell can you recommend?

on the fly not needed, but easy height adjustment desired.

|

|

Bought this JVC Victor UA-7082 for $758. New Rubber Grommet. all misc parts, 60 day return.

was OEM Long Arm Option back when my TT81 was new, fits my existing alternate 270mm hole. Height is good (my Blackbird needs a spacer due to the TT81's wide/thick tapered rim design).

Victor's armtube headshell fitting is not azimuth adjustable like many Micro Seiki models are. I'll use my Pat's, or my Audio Technica Headshells with azimuth adjustment.

I just got two of them with the used AT150e and 160ml cartridge bodys I just bought (both with used ATN160ml stylus with beryllium cantilevers),

/////////////////////////////////////////////////////////////

My NewArtVinyl Blackbird 12.5 Arm is fixed cartridge and is giving me trouble. I am a firm practitioner of properly set anti-skate for fidelity, balanced l/c/r imaging, improved contact surface area while preventing/reducing uneven stylus/groove wear.

My Blackbird's original delicate Litz wire's silk insulation was damaged by movement against the sharp edge of the hole it passes thru in the arm base (design flaw). they now make it with an integral 5 pin din connector (above the plinth).

Litz Wire Fun

VAS re-wired it, BUT they put a protective sleeve that is too stiff, I am unable to get a full arc of free movement without a speck of tonearm wire resistance, or set anti-skate reliably.

After I mount the UA-7082, I will widen/round the edges of the Blackbird plate's hole, and remove the stiff protective sleeve on the wires, which will hopefully allow free movement for anti-skate forces to be accurately set.

|

@lewm, I speak from some experience since I own a 505. However it was used when I got it and the stub was not in the same plane as the arm tube. After some investigation I found MS designed it to be in a single plane, so I had mine repaired as new.

However I didn't audition it before and after. I'm not familiar with the JVC arm although I know it has a solid reputation.

|

I owned a nice 505 too, but because I had no TT that could easily mount it, I eventually sold it without ever having used it. Beautiful craftsmanship for sure. My fallible recollection is that the CW stub extended straight out from the rear of the pivot at the same height as the arm wand but I certainly could be wrong. Anyway, Elliot owns one, so he can set me straight.

|

I did not need to mess with my friend's MA-505 or 505L counterweight section

a thin gasket that could deteriorate is seen here

I took a defective Victor UA-7045 apart, measured, found a solution in Home Depot plumbing dept, gathered new and old info here in 2020

bad victor gasket discussion here

the Victor Gasket is a stepped design, the front portion is smaller diameter and is drawn inside the end of the forward tube, the rear portion is the same diameter as the tube and is seen separating the rear counterweight tube from the front main arm tube

the Victor Arms gasket definitely deteriorate, the one I bought seems to have been renewed, but until I take it apart, I cannot be sure. There is a brass piece within that prevents rotation while tightening, I will verify it's condition

many photos of victor gasket problem here

|

Yes, no one disputes that the Victor tonearm counterweights tend to sag over time. Happens to the best of us. Chakster used to describe this problem as an indication the tonearm was ruined thereby. You and several others were able to fix the problem. Good on you. I've got a bag of faucet washers, some of which are tapered when viewed in cross-section. Perhaps I will give it a shot, though at present I have no use for my Victor UA7045. Maybe there's no Home Depot in Russia.

|

I found my measurements of the Victor concealed brass piece and measurements of the gasket I found at home depot

I will take the 7082 I just bought apart when I receive it, go again to Home Depot, find the part number, take pics, measure the inside diameter this time.

|

I'm looking for the part number of the washer in your diagram. I don't see it. Do you have the number? If so, and if you would share the info, that would be great.

|

Lew; It’s apparently a back burner project for Thom but involves a new machined stub… My enthusiasm for it…whatever it is..has waned over time as my arm went back to Tri last winter for the CF , wire and other upgrades… a hyper clear sonic change for my system anyway…

Re on the fly… and “ grub screw “…. generally i agree…but my 505… the Dynavector is a glorified grub screw….

|

lewm,

you are the reason I will take it apart and go find a washer that works and make a note of the part number when I do. Arm is about to ship from Japan.

I'm hoping everything is good inside, won't know till I take it apart. If not I have 60 days to return it.

|

Elliot, That is a very kind offer, but please don't go to the trouble. I have a big bag of faucet washers, many of which have a promising profile, and I can find one that works by trial and error and thanks to the dimensions that you posted. I've got an excellent metric caliper that will help too. Keeps my mind off you know who(m).

The DV505 VTA adjuster is not so great compared to that offered by many modern tonearms, but it is light years ahead of the family of tonearms that place an actual grub screw at the base of the pillar with no gearing to keep the arm stable while you move it (by hand) up and down. The DV505 at least has a gear built in to move the pivot up and down in small increments, and it's relatively easy to secure the adjustment once you are satisfied.

|

|

For anyone with an older "primitive" arm such as lewm just described, here’s a trick I read years ago for adjusting VTA.

If there is space, use a deck of playing cards to secure the height of the arm before releasing the grub screw. Then add or remove cards as necessary to adjust to the desired height, then tighten the grub screw.

Not recommended "on the fly".

|

Disappointedly, my early model Blackbird Arm post is not as tight a fit in it’s arm base tube as Thorens or SME precision. I had NewArtVinyl add a 2nd allen head set screw (current production change along with the 5 pin din connector so you don’t need to terminate the silk covered Litz wires yourself like I did),

I need to loosen two set screws, adjust the height up/dn, tighten two set screws; definitely not ’on the fly’. but their micrometer method provides for ’precise’ up/dn

you put something between the plinth and the micrometer’s tip so the arm stays where it is when it’s set screws are loose, then turn the micrometer for up or dn: not easier, but more precise than any arm I have adjusted. You can record the micrometer’s settings if you want to recover prior determined positioning.

|

|

What am I looking for? I see the entirety of the old thread.

|

lewm

I find it humorous when a google search finds something I created that I had completely forgotten about, a chuckle, then I forget again. I didn't read it yet, just wondered if you remembered it, maybe something useful there.

|

|