@8th-note,

.

~ ~

Is this what you are looking to buy? You do know it is 120/240V? Best practices is to feed audio equipment, (that is connected together by wire ICs), is to feed the 120V equipment from branch circuit breakers fed from same Line. All from Line 1 or all from Line 2. Not from both.

You mentioned Michael Fremer’s new electrical service. All his audio equipment is fed from one 120V Line. I have no idea how big his total load is though. Just a guess a lot more than yours.

.

~ ~

I watched the video again today and picked up a few things I missed the first two previous times. I believe there are a few things worth noting.

Near the end of the video Fremer shows the new sub panel for his audio room. It is fed 120V only. *(1)* Electrical Inspector did make the electrician install the other 120V hot conductor. It will not be used though. I think it was just an AHJ Inspector thing. I couldn’t find anything in the NEC that requires it.)

Note the 120V feeder for the sub panel is installed in PVC conduit. All the branch circuit wiring is installed in non metallic flexible conduit.

Example, non metallic flexible conduit:

1/2-in x 25-ft Ultratite Non-metallic Schedule 80 Liquid-tight Conduit

From what I could see the outlet boxes are also non ferrous as well as the outlet cover plates. I did see something I didn’t agree with though. Two dedicated circuits for the two mono amps were pulled in the same raceway, conduit. That doesn’t follow best practices. I did notice though the 120V Hot, Neutral, and Ground branch circuit wiring used for each 120V circuit was apparently tightly twisted together. That would be a whole lot better than if single conductors for both dedicated circuits were all pulled loosely together in the conduit. That definitely is a no, no. A sure way to induce an AC voltage onto the equipment grounding conductors and cause ground loop hum.

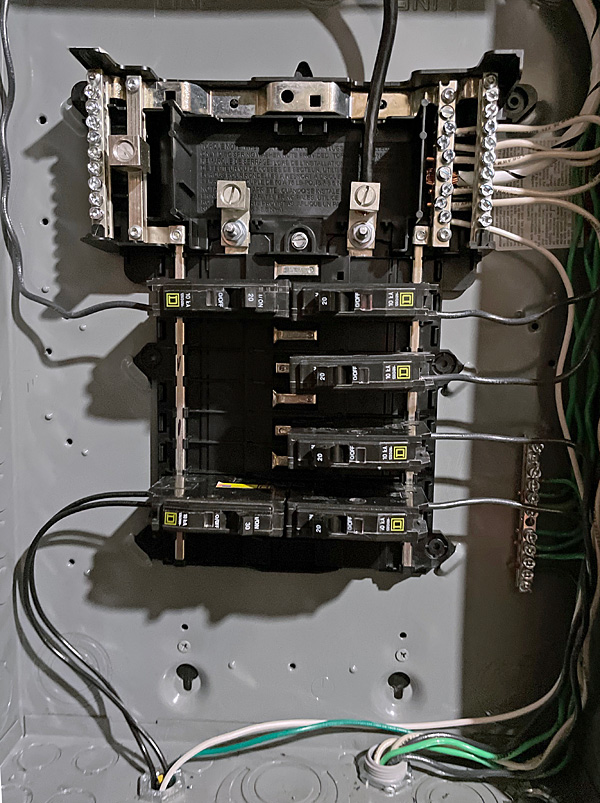

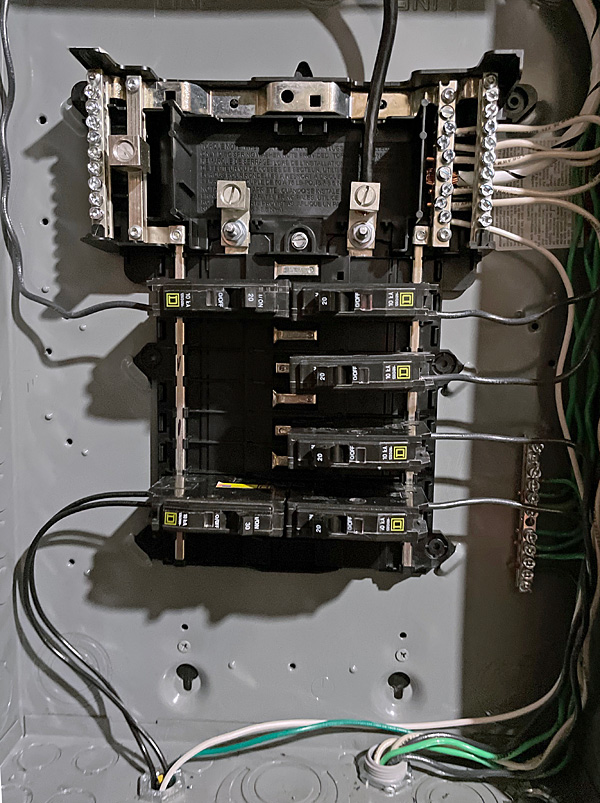

Image of audio room sub panel, front cover removed. Note the two 120V dedicated circuits bottom right side of panel in the flex conduit connector.

.

.

/ / / /

Not to bad mouth the electrician. He may have had his reasons... I did notice a few things on the installation of the new electrical service I didn’t care for.

The use of a rigid no-thread coupling on the Mast rigid Conduit. (Yeah it meets code. But...)

The use of the offset nipple into the top of the meter socket enclosure hub. Not pretty...

And I found myself scratching my head why the electrician used PVC conduit nipple from the bottom of the meter socket enclosure to the Myers Hub on the main service equipment panel. A galvanized rigid nipple would have looked a lot better, jmho... As well as electrically bonding the two metal enclosures together.

/ / /

*(1)* Electrical Inspector did make the electrician install the other 120V hot conductor.

I have a friend in Texas that has a 15KVA 240V to 120V single phase pad mount outdoors isolation transformer strictly for feeding his two channel audio room equipment. The electrician only installed one, Hot, neutral, and ground, conductor to feed the 120V only electrical panel. The electrical inspector made the electrician add the additional spare conductor for the other hot Line, ( for future), not used, not connected.

.